RDT - RD® pile with new threaded splice

SSAB has renewed threaded splice for drilled RD piles. New thread profile is designed for robust, easy and fast splicing in job site conditions. New design meets all the pile splicing requirements given in EAD and it is CE marked.

Advantages and properties of new threaded splice

- Reduced installation time. Less turns needed during splicing.

- Identical sleeve for all available steel grade and wall thickness combinations in each pile diameter where threaded splicing is available. Always right sleeve selected and less waste thanks to the possibility to use same sleeve in all job sites.

- The tensile strength of a splice is guaranteed to be 50 % of the compressive strength of the pile.

- High-quality end result also in difficult installation conditions.

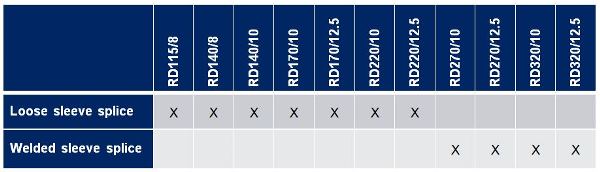

Availability of threaded splices (steel grades S460 and S550)

Installation of loose sleeve splices with left handed threads for DTH drilling

- Remove dirt from threads if necessary before tightening

- Apply lubricant on sleeve threads

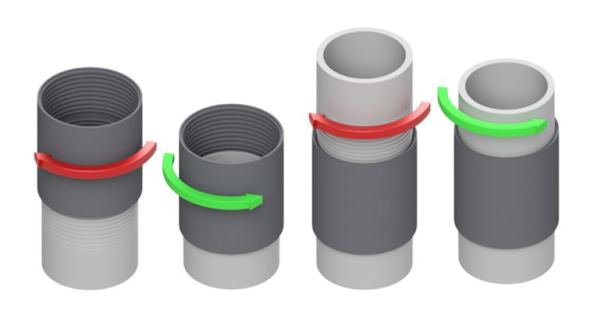

- Rotate sleeve clockwise until thread settles (See figure 1)

- Tighten sleeve counter-clockwise on top of pile relatively tight (See figure 2)

- Tightened sleeve makes coupling of next pile element easier - Place next pile element on top of the sleeve

- Rotate upper pile element clockwise (open thread) until thread settles (feel or hear a click) (See figure 3)

- Thread settling is easier with properly tightened sleeve because the sleeve does not rotate with the pile element - Tighten the pile to sleeve with required tightening torque (See figure 4)

Steps of tightening threads presented below in figures 1-4:

Installation of welded sleeve splice is as above without phases 3 and 4.

Right handed threads available for top hammer drilling.

More information on RD piles: RR and RD piles Design and installation manual

Bilagor

Kategori och taggar