How to bend

What is press braking?

Just like you can fold a sheet of paper, you can also fold a steel plate — but it requires different tools than your hands and careful consideration of the material.

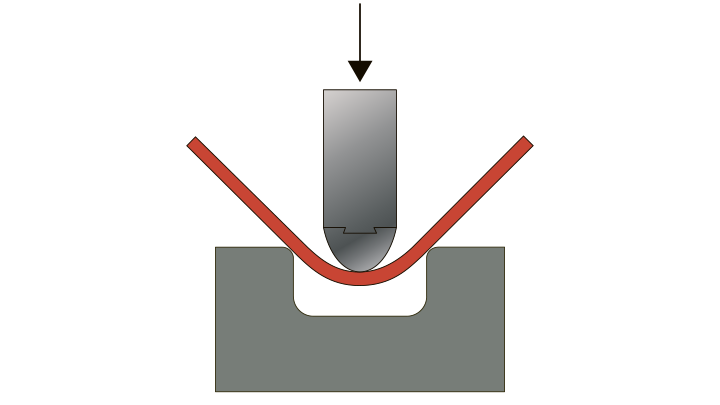

In steel fabrication, a press brake is commonly used to apply force from one direction against a resistance tool, causing the plate to change shape.

The process involves two main components: the punch (upper tool) and the die (lower tool). This setup enables the formation of one bend at a time.

Press Brake Machines

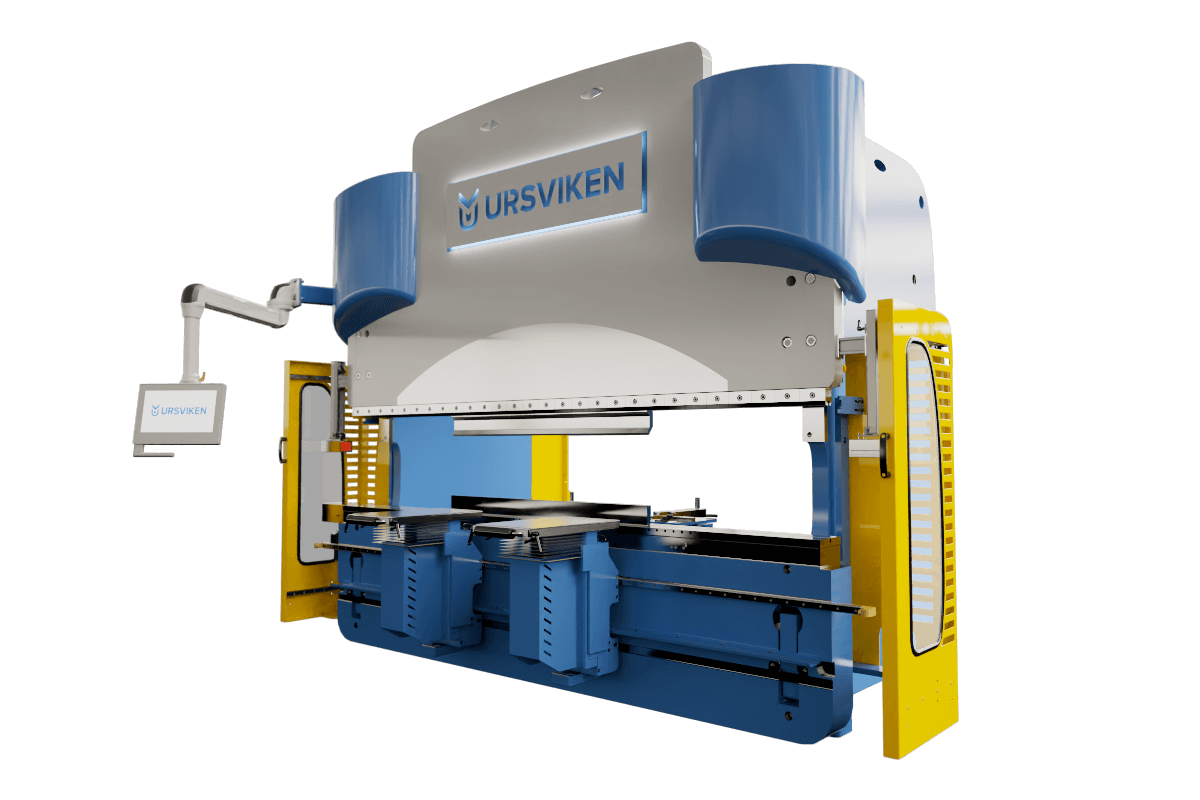

Press brakes are available in a variety of sizes and tonnages, with their capabilities determined by factors such as material thickness, bend length, and required precision. These versatile machines are widely used in the manufacturing of metal components, including brackets, panels, enclosures, and other sheet metal parts.

CNC bress brake machine. Photo: Ursviken Technology AB.

Importance of safe bending

Use the correct bending tools and follow recommended guidelines to prevent accidents. This example shows how a plate can fail during bending when a punch that is too small is used.

Safe use of punch and support tools

It is essential to consult the tool manufacturer's specifications and guidelines to determine the recommended tonnage.

Flange height

If the flange height is too small, the workpiece may slide into the die during bending, which can pose a safety risk.

Basic setup for press brake

The basic principle of bending is that a force is required to cause permanent deformation in the material, along with proper support for the steel.

Press force for press brake operation

Press force is required to deform the material.

Press brake machines

A press brake is a machine tool used in steel fabrication to bend or shape steel plates.

Springback

Springback in bending occurs when the material attempts to return to its original shape after being bent.

Edge and surface conditions of bended specimens

Surface and edge conditions can significantly affect bending quality and may lead to cracks in the bent zone.

Die

The most common types of dies are V-dies and U-dies (see illustrations). A V-die features an angled bottom, which helps guide the material during bending and allows for overbending to compensate for springback.

Die width

When plate thickness increases, the die width often needs to be increased as well.

Air bending is recommended when bending high-strength steel

In bottom bending, the bending angle is limited by the plate making contact with the bottom of the die.

Punch

Punches are used to form the plate into the die.

Separation between plate and punch

With higher tensile strength, the material tends to separate from the punch during bending.

Lubrication

Required punch force is often high when bending high-strength steel.

Crowning

Crowning in bending is a design and manufacturing technique used in metalworking.

Recommendations

Within SSAB, we provide bending recommendations for all our steel brands.

Maintenance of Press Brake Tooling

Maintaining press brake tools is essential for ensuring the longevity and optimal performance of the machine.

BendCalc

SSAB has developed an app for calculating bending parameters—BendCalc.