Speed and accuracy made watertight RD® pile wall the best solution to surround a 640 000 cubic meter excavation for a car park in Pasila Tripla

Pasila Tripla is a massive billion-euro construction project near the city center of Helsinki in Finland. Customer’s challenge was to find a watertight retaining wall solution in demanding soil conditions. Location in busy urban environment, five minutes from downtown Helsinki, is critical requiring just-in-time deliveries and fast installation. The location is right by a bridge with foot traffic, railway track and busy Pasilankatu street. Delivery and installation speed were critical for the customer: it was important to have piles delivered in one piece to avoid additional welding at site. The retaining wall cuts through groundwater layers, which exerts an enormous pressure on the underground structures making water-proofing the retaining wall demanding. SSAB‘s RD pile wall solution enabled fast installation with tight tolerances. Accuracy and speed in addition to water tightness made RD pile wall best solution for the customer.

Figure 1. Installation speed was the biggest reasons for the customer to choose RD Pile wall.

The development in central Pasila is among Helsinki’s most significant projects over the coming years. Pasila Tripla will encompass three city blocks including a shopping center, public transportation hub, housing, hotels and offices. The total area will be 183 000 floor square meters and total value is over one billion euros. Pasila Tripla will have 3 000 inhabitants and 15 000 workplaces. The construction project will be completed in stages by the early 2020s. Shopping mall part will be ready in 2019 and 1st apartments in 2020. City of Helsinki arranged a design competition PasilaOne during 2013-2014, which was won by YIT’s proposal Pasila Tripla.

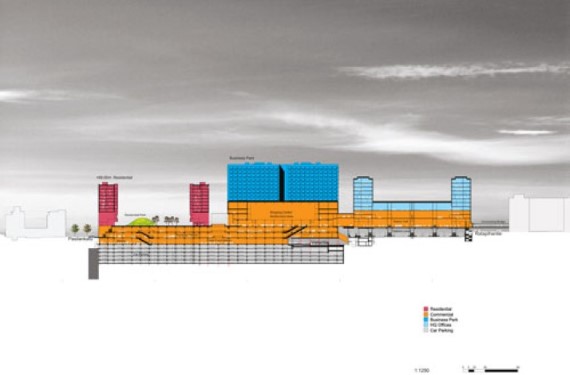

Figure 2. Pasila Tripla consist of a total area of 183 000 floor square meters and its total value is over one billion euros.

Figure 3. RD Pile wall surround the excavation for the underground car parking area.

Challenging conditions for the retaining wall

The retaining wall at the Tripla site will cut through groundwater layers, and prevent natural groundwater flow. To ensure water flow in ground, a pumping system is needed to transfer water from northern side of underground car park area to southern side. Also the installation place is close to listed old brick buildings, constructed on wooden piles and ground-bearing foundations, which need to be protected. Water-proofing the retaining wall was a demanding task due to the fact that the groundwater exerts an enormous pressure on the underground structures. Only 20l/min of water is allowed to seep into the excavation. Design life for the retaining wall is 200 years with corrosion allowance of 6.5 mm. It forms a visible wall surrounding to the parking facility.

SSAB’s delivery

SSAB delivered close to 4 200 tons of piles, totally 13 500 square meters of RD pile wall. This meant over 130 on time deliveries to the construction site in less than six months. Delivery consists mainly of RD700/14.2 in S440J2H pile pipes with RM/RF interlocks welded to them. The pile lengths were ranging from 5.5 m up to 33.5 meters installed in one pieces. There was no splice welding needed. RM/RF interlocks were provided with bitumen sealant. Pile wall was installed in three phases: first by vibrating through clay and sand layers to the top of the moraine layer, then augering the pile pipe empty and finally drilling through moraine into the bedrock. After that the piles were reinforced and concreted. Installation method was least risky for the surroundings compared to other solutions as removing the clay with auger creates little to no spatter. Also small amount of RD400/12.5 S440J2H pile wall was included in the delivery. RD400/12.5 piles were reinforced by inner RDs320/12.5 pipes. RD400/12.5 pile wall was drilled under existing railway platform.

RD pile wall was supported by temporary strand rock anchors installed drilled casing tubes. All together 800 pieces of casing tubes were delivered including 14.2 km of soil drilling and 6 km of rock drilling. Casing tubes were threaded RDc140/5 and beveled RD140/5 and RD170/4.5. Walings were delivered by Tibnor, part of the SSAB Group. Total amount of beams was almost 900 tons including HEB 300, HEB 360 and HEB 400.

All anchors will be finally deactivated and the support will be implemented with the floor slabs of the parking facility.

“The steel piles were transported in one piece from our site in Oulainen, Finland. These are the longest large-diameter steel-pipe piles we’ve ever delivered for a RD pile wall project. It is also the largest delivery we’ve made, even though we have provided similar solutions to other customers in the Nordic region and as far away as the Waitaki power station in New Zealand,” says Jari Mara, Business Area Manager, SSE Infra Finland.

Figure 4. Steel piles were transported in one piece with lengths up to 33.5 meters.

SSAB’s delivery started in May 2015 and the RD pile wall was installed by mid November 2015, according to plan. This was followed by excavation and anchoring in five to seven levels. Last casing tubes for the anchoring will be delivered in June 2016.

SSAB’s delivery:

- SSAB RD pile walls

- 754 pcs RM/RF-interlocked drilled piles RD700/14.2, 16 700 m in total

- 60 pcs RM/RF-interlocked drilled piles RD400/12.5, 1 300 m in total

- 60 pcs structural pipes RDs320/12.5, 1 300 m in total

- Casings for anchors: 800 pcs RDc140/5.0 + RD140/5.0+ RD170/5.0, 20 200 m in total

Co-operation partners:

- Project owner: YIT Rakennus Oy

- Main contractor: Keski-Suomen Betonirakenne Oy

- Drilling contractor: Fort Ehitus OÜ and YIT Rakennus Oy

- Drilling consultant: Ilmi Solutions Oy

- Drill bit supplier: Robit Oyj

- Design: Ramboll Finland Oy

YIT’s massive construction project Pasila Tripla still lasts couple of years and the co-operation with SSAB continues. SSAB has already started smaller RD pile wall deliveries for shaft structures and pile deliveries for building foundations.

RD Pile wall – Retaining wall structures based on steel piles

Based on RD piles (RD220–RD1200) and installed by drilling, RD pile walls are suitable for retaining wall structures in demanding ground conditions. RD piles are connected by welded interlocking sections, creating a continuous pipe pile wall against horizontal and vertical loads. The RD pile wall is installed with an oversize ring bit instead of a normal ring bit. The RD pile wall is always installed by percussion drilling methods, using a DTH hammer. The drilling method is centric.

Pile pipes used in RD pile walls are SSAB’s drilled RD220-RD1200 piles. RD piles are special piles, installed by drilling in difficult ground and environmental conditions. RD piles are based on longitudinally or spiral welded steel pipes. The generally used steel grade of RD piles is S440J2H, but grades S355J2H and S550J2H as well as X60 and X70 are also used. Pile pipes for the RD wall are spliced by welding.

In the RD pile wall the pipe piles are attached to each other by interlocking sections. Adjacent piles are always interlocked using a pair of interlocking sections, a narrow and a wide one. Two different interlock types developed for the RD pile wall are available: the SSAB RM/RF interlock and the SSAB E21 interlock. SSAB’s new RM/RF interlock and the injection channel integrated in it ensure the water tightness of the toe of the RD pile wall and its rigid contact with rock without separate injection pipes.

Figure 5. SSAB RM/RF interlock and integrated injection channel ensure water tightness of the toe of the RD pile wall.

Attachments

Category and tags