RR piles were the most cost-efficient solution for the foundation of new sawmill in Lieksa, Finland

New saw mill is being built in Lieksa, a town located in North-Karelia in Finland, to replace old saw line. Since 2017 the owner of Lieksa sawmill has been Austrian company Binderholz GmbH, who has recently been investing on sawmills in Finland. The time schedule for the foundations of the new sawmill has been very ambitious. Piling started at the job site only 3 weeks after the first inquiry was left to piling contractor Kankareen Paalutus Oy and the piling was finished in four weeks.

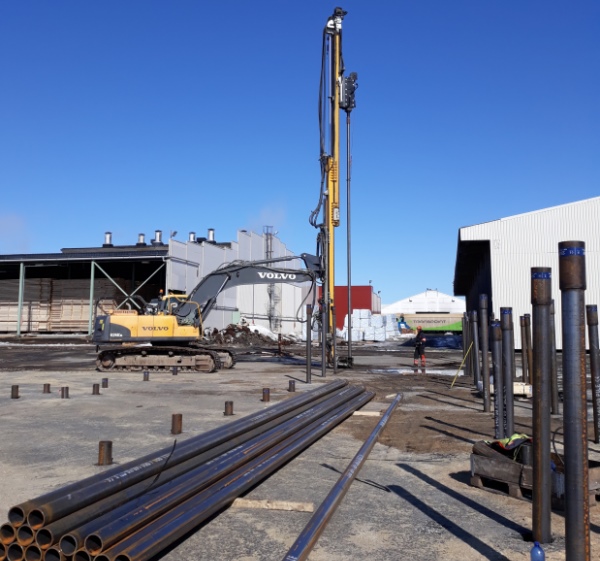

The ground conditions at the site were challenging since there were down to five meters of fill layers with boulders. Instead of drilling Kankareen Paalutus Oy decided to do test piling with driven RR piles in size RR140/10. Test piling was able to be organized already two days after the inquiry was placed. It proved to be the right and most cost-effective solution for the project.

Piling work was done during one month. SSAB delivered in total 16.1 kilometers of RR140/10 piles in S440J2H steel grade. 475 tons were delivered as pile elements and 61 tons were delivered as pile pipes. Kankareen Paalutus had 2 piling machines at the site, the other one for 6 meter pile elements and the other one for 12 meter pile elements. Pile lengths vary from 15 to 20 meters.

“RR pile was definitely the right choice for the ground conditions in this project. Installation was successful despite of the fill layer with boulders thanks to the high strength of steel pile and use of hydraulic ram. Hydraulic rams are rapid percussion pile drivers. Larger pile size would have been required for other driving equipment, which would have resulted in higher costs. Also our customer was very satisfied to the project execution.” says Hannu Vesamäki, Technical manager, Kankareen Paalutus Oy, and continues: “All deliveries were on time, there was delivery plan made beforehand. We were satisfied with the deliveries and the delivery speed, although there were some changes in our needs between 6 m and 12 m piles during the 3 week period of deliveries.“RR piles were installed by the end of April and the saw mill will start operation during winter 2018-2019.

Piling work was done in one month. SSAB delivered in total 16.1 kilometers of RR140/10 piles in S440J2H steel grade.

RR pile together with installation with hydraulic ram was the right and most cost-efficient choice for the ground conditions in this project to go through the 5 meter fill layer with boulders.

Attachments

Category and tags