Underpinning in Turku City Centre

As Oy Brahenlinna is a residential building in Turku City Centre. During recent years the building has been settling unevenly. Installation of new piles to stop the settlement is ongoing.

The eight story building has been built in 1957. Originally the building was made non-settling by founding it to moraine layer with long wooden piles spliced from two logs. Totally old foundations have 728 wooden piles which each have an allowed bearing capacity of 15 tons.

Figure 1. As Oy Brahenlinna

During the time the building has started to settle slowly and unevenly. During recent years the speed of settlement of the building has been 0 to 4 millimeters per year. Uneven settlement has not caused any cracks to structures yet, but inclined floors have caused some problems for the residents.

The reason for settlement is not totally known. The wooden piles have not been found to be decayed. Most likely old wooden piles have not been driven tight enough to the bearing layer. This has caused the toes of wooden piles to slowly settle deeper into the moraine layer.

Main reason for the underpinning of the building is imago. The building has been founded on wooden piles and it has been settling. In Turku area this causes remarkable reduction for the prices of apartments and for the overall imago of the building.

There are about 300…400 old buildings founded on wooden piles or straight on top of very soft clay layer at the central area of Turku. Over 100 of those have already been underpinned during past 20 years. Most common way of underpinning is installation of new steel pipe piles, since they can be installed effectively in low headroom and limited access situations.

Piling with drilled RD and RDs piles in basement

New piling is done with drilled RD and RDs piles. Four different pile types are used in the project; RD140/8, RD140/10, RDs170/10 and RDs170/12.5. “SSAB has very good selection of different pile sizes. This enables designer to optimize the design and to reduce the amount of piles under heavier loads.” says Jarno Rajakallio, structural designer at Sweco Rakennetekniikka Oy. “In this project we ended up with four pile types but only with two different pile diameters. Same diameter enables use of same drilling equipment, but different wall thickness enables optimization of resistance.”

Total number of piles is 103 pcs. Lengths of the piles are almost the same; the lengths are varying from 29 to 30 meters. Total amount of piles is about 3,000 meters.

The courtyard area of the building is in the use of residents during the whole project time. This causes naturally some special arrangements for storage of construction material. “With this kind of projects there is often very limited space available around building for material storage”, says Esko Kauti, site manager of Skanska Infra Oy. “We ended up using our own depot near Turku to store pile elements. Trucks from SSAB deliver pile bundles there and then we use our own transportation to bring only small amounts of piles at the right time to site. This arrangement has helped us a lot.”

Almost all piles are drilled from inside the building, from the basement level. Confined spaces require small piling rigs and other special techniques. In most of the area the height of the basement is 2.2 meters, but in almost 1/3 of the area the height of the basement is only 2.0 meters. Small drilling rig is shown in Figure 2.

Figure 2. Small drilling rig for underpinning projects

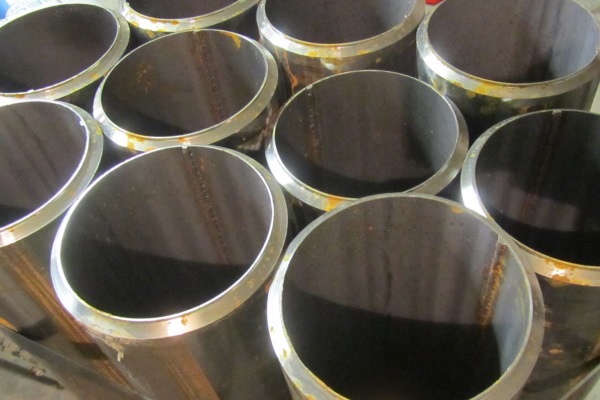

Piles are made from 1.0 m and 1.2 m long elements. The splicing of the piles is done by welding. Both hand welding and mechanized robot welding are used in this project. For mechanized robot welding a special type of beveling is used, shown in Figure 3. The quality assurance of welding of splices contains pre-tests on-site and ultrasonic testing for certain amount of welds according to Finnish Piling Manual PO-2016.

Figure 3. Beveling type used for mechanized robot welding

Huge amount of old wooden piles has caused some problems during installation of new piles. Almost all new piles are having contact with old wooden piles during drilling. This naturally causes some delays, since drilling through wood is much slower than through soil. Bigger problem than delay is possible damages the drill bits can be facing from contact with wooden piles and especially from contact with steel parts at the splices of old wooden piles. At the moment almost 14 % of installed piles have been abandoned due to these damages.

Very little disturbance for old foundations

Underpinning work always causes some disturbance for the old foundations. In this case the settlement speed of the building has not increase due to underpinning. Most likely this is due to good condition of the wooden piles.

Piling work started at April 2017. According to schedule the work should be ready and premises returned to residents at the end of the 2017. At the end of August half of the piles had been drilled.

Main contractor: Skanska Infra Oy

Structural design: Sweco Rakennetekniikka Oy

Geotechnical design: Ramboll Finland Oy

RD pile supplier: SSAB Europe Oy

Attachments

Category and tags