Vestfold Vann IKS is continuing their water mains DN1000 pipeline in Hunstok-Akersvann, Stokke, Norway

SSAB delivers last 2 100 m of DN1000 water mains to Hunstok-Akersvann during December 2016 - February 2017. SSAB’s delivery content for this project includes totally 15 km of coated DN1000 water pipes and fittings during 2014 - 2017. Delivery consists of 16 m long and 5 tons pipes and pipe fittings to the site. All pipes and pipe fittings are externally and internally coated. SSAB’s OV welded joint facilitates installation and allows 2.0 degree bends at joints. Since the OV welded joint is welded from the inside to make it tension resistant, it is suitable for diameters ≥DN 600 and pressures up to 20 bar.

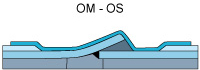

Figure 1. SSAB’s OV welded joint is used in water lines to facilitate installation and to allow 1.5 – 3.0 degree bends at joints.

SSAB is able to produce and deliver by trucks coated pipes quickly and just in time taking into account any changes with time of delivery during the project.

The biggest challenge is to transport and move 16 m long and 5 tons heavy pipes to wet fields before installation within a very short time frame and in very variable winter conditions.

"We chose SSAB to supply the coated steel pipes and fittings because it provides good quality and fast and flexible delivery to the site by trucks“, says Einar Klavenes, Vesfold Vann, Project manager. Vestfold Vann IKS has been established 1968 and is owned together by 10 municipalities in Vestfold county in south part of Norway. The mission of Vesfolf Vann IKS is to offer the partners drinking water of good quality.

SSAB’s main partner is Brødrene Dahl AS and main contractor Arne Olav Lund AS.

SSAB’s water mains offer a reliable and economically advantageous solution for water supply. SSAB's welded steel pipes can be used in water mains where the maximum operating pressure is usually 16 bar. Pipe fittings are delivered for diameters ≥ DN 400. The water mains and fittings are delivered flexibly according to the customers’ wishes. The long lifespan of steel pipes is ensured by an external polyethylene coating and an internal concrete or epoxy layer suitable for use with drinking water. There are also suitable inside coatings for sewage and rainwater. The various connection methods can be carried out by welding or with flanges, connectors or sealed sleeve joints. SSAB has long experience from large and demanding pipeline deliveries.

Attachments

Category and tags