Fast and easy installation of SSAB C210/130X4 median barriers to highway VT23 in Finland

SSAB's median barrier is an effective way of improving traffic safety. Median barriers are used on roads between opposing lanes to prevent collisions between vehicles. Kuu Ras Oy installed SSAB C210/130X4 median barriers to passing lane in Kypäräjärvi in September. SSAB’s delivery to highway VT23 included 1 860 m median barrier and 3 780 m side barriers.

Figure 1. Kuu Ras Oy installing SSAB’s median barriers in Kypäräjärvi passing line in September.

This was the first installation of SSAB C210/130X4 median barriers for Kuu Ras Oy. According to Kuu Ras Oy this median barrier is faster and easier to install than the previous model, Box beam. The connection is better and it includes fewer screws which makes it faster to install.

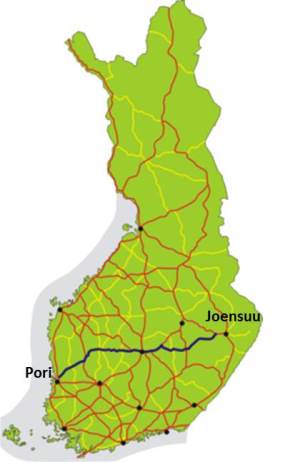

Figure 2. Highway VT23 is 517 km long from Pori to Joensuu. Kypäräjärvi passing line is situated 80 km before Joensuu. (photo: www.wikipedia.com)

SSAB C210/130X4 has replaced the old model of median barrier, Box beam. “The aim was to develop economical solution for customer. Cost efficient installation was one key driver. Number of components has been minimized. SSAB C210/130X4 has only 8 screws per splice when the previous model, Box beam, had 20 screws per splice. Also there are no special screws with limited availability required. Only 2 types of screws are needed, which also promotes easiness of installation”, says Arja Häihälä, Sales Manager in SSAB. “In addition to fast and easy installation, cost efficiency of the median barrier system has been improved by introducing high-strength steel grades”, she continues.

Figure 3. SSAB C210/130X4 median barrier enables cost-efficient installation.

CE-approved and crash-tested median barrier

SSAB’s median barrier is crash tested and compliant with the requirements of the standard EN13172. It has proven its durability in demanding environmental conditions. The high-strength median barrier meets the requirements of impact containment levels H1 and N2 and has been CE-approved.

- The system incorporates several solutions that improve the cost-efficiency of the barrier:

- The barrier system is made of open section and incorporates an innovation that eliminates tight post length assembly tolerances from the installation process.

- End anchors can be installed without drilling through asphalt layers, speeding up the installation of end anchors.

- The number of screws in rail splices has been minimized to speed up installation.

- Rail length is 12 metres.

- Rail posts placed at four metre intervals can be imbedded directly in the ground or pre-installed sockets. Socket installation can be used for example with opening sections.

Figure 4. SSAB safety barrier solutions include median barriers, side barriers and a selection of rails and posts.

Sales and Technical support

Arja Häihälä

Sales Manager, Safety barriers

Mobile phone: +358 40 046 4534

Send email: [email protected]

Design HTML

Attachments

Category and tags