Recently launched RD270 threaded pile element enabled fast and easy piling in Uddevalla, Sweden

New product answered to increasing demand of having mechanical splices also to larger RD pile sizes. Skanska used the threaded pile element first time in the project Skeppsholmspiren in Uddevalla, Sweden. Uddevalla is situated on the Swedish West Coast, north of Gothenburg and south of Oslo.

Figure 1. Skanska’s project Skeppsholmspiren was located in harbor in Uddevalla, Sweden.

The project was originally designed for concrete piles. The original method was however rejected because the inclination of surface of the bedrock was so steep. Due to these demanding conditions, drilled steel piles were chosen. Gunnar Holmberg from Skanska Teknik was responsible for the design of piles used in this project. Customer asked SSAB to deliver RD270/12.5 piles with threaded mechanical splices. SSAB’s development of the new product was just finalized and it was possible to launch the new product just on time for this project. “We were very satisfied with the product. The piles were easy to handle at the site since there were no heavy sleeves. Time savings were remarkable when there was no need for welding outside. Thanks to the mechanical splicing, the weather conditions didn’t play any role in the progress of the piling work. Threads worked well in all conditions”, says Skanska Grundläggning’s project manager Victor Gillholm.

Working site manager for the project was Per Nabrink from Skanska and Foundation Drilling Sweden was in charge for the piling. They were both satisfied with the new product and managed to finish the piling couple days earlier than planned. Also safety at the construction site was highlighted as a benefit over welding. The harbour authorities in Uddevalla were impressed when they saw the piles and threads at the site and were convinced that the horizontal loads are secured with the mechanical splicing. SSAB’s delivery consisted of 35 piles in total. The bottom elements of piles were 14 m long and the length of the upper pile elements varied. Skanska was in overall satisfied with the project and chose to use RD270/12.5 piles with mechanical splices also in their next project in Visby.

Figure 2. SSAB’s delivery included 35 piles.

Mechanical splicing guarantees uniform quality and reduced welding on site

As proven in the customer case described above, mechanical splicing eliminates the need for splice welding on site. Welding of a connection on a load bearing structure is always demanding. On construction site the weather conditions can vary a lot, which makes it even more demanding. Many of these weather related difficulties and problems can be avoided when splicing of a pile is done mechanically. The quality of the splicing will be good in all weather conditions.

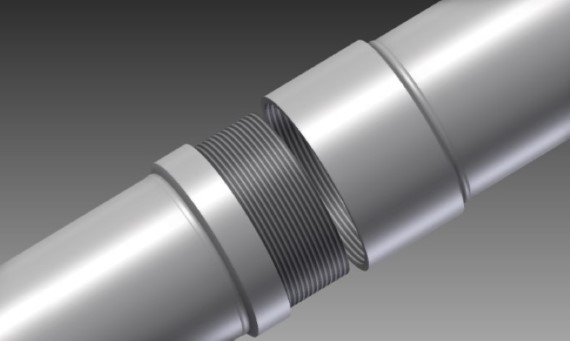

Figure 3. Threaded mechanical splice reduces welding at site.

Threaded mechanical splices for drilled RD piles are available now up to pile size RD270. With pile size RD270 there is not any loose threaded sleeve. In splicing the first pile element has male threads and the second one has female threads. This reduces the time needed for splicing. Also the amount of parts needed to make a splicing reduces. The splice has been tested and approved. The splice meets the requirements given in European Technical Assessment ETA 12/0526 for SSAB’s steel piles and it has been added to ETA. RD270 piles with mechanical splice are CE marked like all SSAB’s steel piles.

To be considered before installation of RD270

The outer diameter of splice section is 298.5 mm, which is larger than pile diameter 273.0 mm. This should be taken in to account when choosing ring bits for drilling to prevent the splice from getting stuck to obstacles. Recommended tightening torque for splice is ≥ 3 kNm.

Basic requirements for mechanical resistance and stability | ||

| Bending resistance and stiffness | Bending stiffness of the pile with mechanical pile joint: EIspliced ≥ 0.75 x EIunspliced (in moment range 0.3 - 0.8 x M) Bending resistance of the pile with mechanical pile joint: Mspliced= Wel x fy | |

| Tension resistance | Tension resistance of the pile with mechanical pile joint: Nt,spliced ≥ 0.15 x As x fy | |

| Compression resistance | Compression resistance of the pile with mechanical pile joint: Nc,spliced ≥ As x fy | |

Attachments

Category and tags