The first project with a new type of RDW drilled pile wall

Housing company Helsingin Pilvilinna is located in Helsinki, in the southeast corner of the new Ratapiha block residential area in Middle Pasila as well as in the immediate vicinity of the Mall of Tripla. In the highest part of the building, there are 12 floors, and there will be 82 apartments in total. The developer for the project is JM Suomi. Skanska Infra Oy is responsible for the piling and the retaining wall structures, while Sitowise Oy will design the foundation structures.

The building is located in the corner of the Firdonkatu and Pasilankatu streets. The building will be based on drilled RDs piles and, for the most part, the foundation level will be significantly lower than the street level next to the building. For this reason, a retaining wall structure was designed for the corner of the lot.

Based on the information available, installing VL603 steel sheet piles at the planned depth would be possible at the Firdonkatu site, whereas at the Pasilankatu site, the soil filling containing large stones and boulders would make it impossible to install the sheet piles.

Image 1. Installed steel sheet piles on the left. In the background, an RDW drilled pile wall is being installed along the Pasilankatu street

According to Skanska Infra's project manager Patrik Thesleff, the main alternative in these kinds of situations is to design a traditional RD pile wall or a soldier pile wall for the site using drilled piles and steel sheets of which the latter is quite slow and could present occupational safety risks.

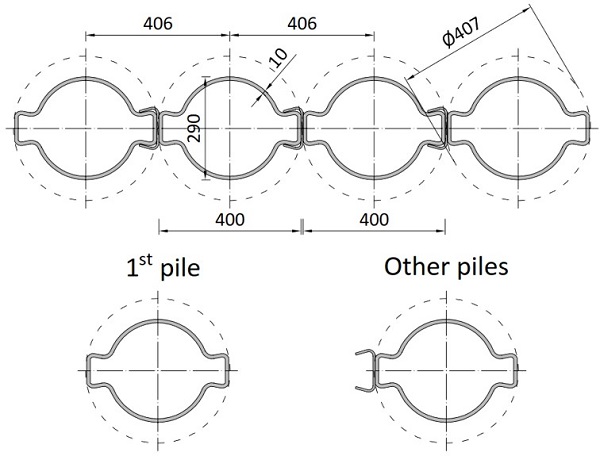

Thesleff had heard of a new type of RD pile wall at SSAB's Steel Pile Day event, and contacting SSAB's pile sales department got the ball rolling. The RDw300x400x10 pile wall is suitable particularly for sites where steel sheet pile walls cannot be installed easily and reliably and where water-tightness of retaining walls is not required. The product can be delivered quickly straight from the stock and, in terms of costs, it is more economical than a traditional RD pile wall.

Image 2. RDW drilled pile wall principle

Between June and July 2020, a total of 103 pieces of L=12m pile wall elements for building just over 40 running meters of pile wall were delivered to the site. The piles were installed using an 8" DTH hammer, Robit standard pilot bits as well as specially designed SR 273/12,7 RDw300x400x10 ring bits.

Image 3. Ring bit SR 273/12,7 RDw300x400x10 and a casing shoe

According to Thesleff, the work was carried out successfully after some initial equipment-related and technical challenges.

During the excavation work it was confirmed that traditional sheet piles would not have been able to penetrate through the layers of soil filling. It was also possible to conclude that this method can be used to penetrate through even large boulders.

Image 4. Soil filling around the wall and penetration through boulders

Wall material costs were clearly lower than those related to a traditional RD drilled pile wall. The aim is to improve product availability straight from the stock in the future.

SSAB's delivery content:

- 103 x L=12m RDw300x400x10 drilled pile wall elements

- RDs170/12,5 S550J2H 122 x 2200m

- RDs220/12,5 S550J2H 146 x 2400m

Attachments

Category and tags