Shape Corp. named Swedish Steel Prize 2019 finalist

The Swedish Steel Prize, which celebrates its 20th anniversary this year, aims to recognize the good engineering, cooperation and steel innovations that lead to a better and more sustainable world. Shape Corp., from the USA, is one of the four finalists for this year’s prize, which will be awarded during a ceremony in Stockholm, Sweden on November 14. The award ceremony is part of a three-day event where hundreds of international participants will take part in seminars and a site visit at SSAB.

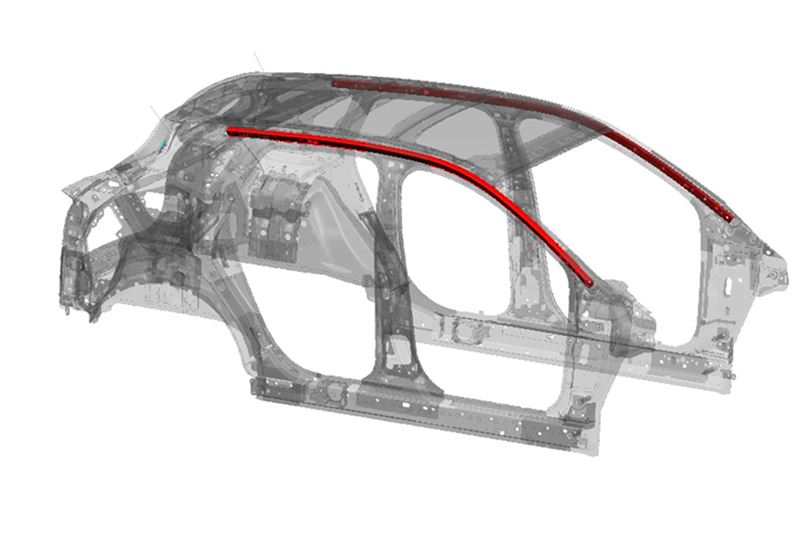

Shape Corp. is nominated for its 3D roof rail tube, a new innovation that represents a first in the automotive industry and will result in both cost savings for OEMs and safer cars for the general public.

“In the mid-2000s we developed bending technology that could bend in one direction in the same plane, in line with our roll forming process. We called it 1D bending, and over the next few years this technology progressed to handling bending in two directions on the same plane – and then three directions. We call it 3D bending,” explains Brian Oxley, Product Manager at Shape Corp.

In 2011, Shape Corp. approached Ford with the profile concept, and it resulted in 3D roll-formed A pillars, made from cold rolled 1,700 MPa martensitic steel, which are currently being used in a number of Ford vehicles, including the Ford Explorer and Ford Escape. Also Docol® 1700M steel will be part of the application.

Traditionally, these types of automotive applications are hydroformed, however, doing so can mean limitations in terms of material strength and production efficiency. Instead, the tube is three dimensionally bent after roll forming and remote laser welded into sub-assembly for integration into the A-pillar and roof rail area in the vehicle safety cage for impact protection.

Thanks to 3D forming, the A pillars feature smaller profiles than traditional solutions, allowing for better driver visibility, more interior space as well as better packaging of airbags. The 3D formed A-pillars also have an improved strength to weight ratio of over 50 percent, which has led to an overall mass reduction of 2.8-4.5 kg per vehicle.

Shape Corp.’s highly innovative technology and use of steel has been proven viable within the global automotive industry and represents a major leap forward in both car safety and automotive design.

“We have taken the highest strength steel on the market and combined it with the perfect application – a bit like pairing wine with food,” explains Oxley. “The results are very tangible in terms of mass savings, but it also shows the industry what is possible with these advanced grades – and that steel will have a place in automotive for a long time to come.”

The Swedish Steel Prize jury’s motivation for selecting Shape Corp as a finalist for the Swedish Steel Prize 2019 is:

Shape has developed a cost effective and robust manufacturing process for 3D shaped tubes that makes it possible to utilize cold forming steels with the highest strength levels currently in existence. With this technology, a unique lightweight solution for A-pillar and roof rail tubes, with minimal section size, is now ready for implementation by a major automotive manufacturer during 2020. This pioneering innovation will challenge other lightweight materials with a much more sustainable steel solution that allows for circular material flows.

For further information, please go to steelprize.com or contact:

Eva Petursson, Chair of the Jury, Swedish Steel Prize, [email protected]

Anna Rutkvist, Project Manager, Swedish Steel Prize, [email protected]

Category and tags