General Product Description

SSAB Domex 420MC meets or exceeds the requirements of S420MC in EN 10149-2. Upon agreement, it can be delivered as dual certified. This dual certification will enable producers of steel structures, in accordance with EN 1090, to use SSAB Domex 420MC in their CE-marked final component or structure.

Dimension Range

SSAB Domex 420MC is available in thicknesses of 1.80-15.00 mm and widths up to 1860 mm as coils, slit coils and as cut to length in lengths up to 16 meters.

Mechanical Properties

(mmin)

(mmin)

(min MPa)

(MPa)

(min %)

(min %)

(x t)

(mmin)

(mmin)

(min MPa)

(MPa)

(min %)

(min %)

(x t)

(mmin)

(mmin)

(min MPa)

(MPa)

(min %)

(min %)

(x t)

The mechanical properties are tested in the longitudinal direction.

Bending properties for both longitudinal and transversal direction.

1) A80 value applies for thicknesses < 3.00 mm.

2) A5 value applies for thicknesses ≥ 3.00 mm.

Impact Properties

Charpy V 10x10 mm test specimens

Charpy V 10x10 mm test specimens

Charpy V 10x10 mm test specimens

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(min %)

(max %)

(max %)

(max %)

The steel is grain refined.

1) Meets the requirements of category A (thin coatings) for hot-dip zinc-coating in EN 10149-2. Category B for thick coatings is available on request (Si 0.15-0.21%).

2) The sum of Nb, V and Ti is max 0.22%.

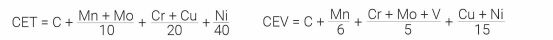

Carbon Equivalent

Tolerances

SSAB Domex is delivered with SSAB Domex tolerances, with improved guarantees compared to EN 10051. More details are available at SSAB.com

Thickness

SSAB Domex thickness tolerances correspond to 2/3 of EN 10051 as default value. After special agreement, tolerances down to 1/3 of EN 10051 can be delivered for certain products and dimensions.

Length and Width

SSAB Domex tolerances for width and length are according to SSAB standard and offer narrower width and length tolerances compared to EN 10051.

For coil and sheet with mill edge, the width tolerances are corresponding to -0/+20 mm.

For coil and sheet with cut edge, the width tolerances are corresponding to -0/+2 mm.

After special agreement, tighter tolerances can be delivered for certain products and dimensions. Length tolerances only apply for cut to length sheets.

Shape

According to EN 10051. Narrower tolerances are available on request.

Flatness

SSAB Domex tolerances guarantee a maximum flatness deviation of 3 mm/m in addition to the EN 10051 flatness requirements.

Flatness guarantees only apply for cut to length sheets.

Surface Properties

According to EN 10163-2 Class A, Subclass 3.

Delivery Conditions

Thermomechanically rolled.

Surface and edge condition

Fabrication and Other Recommendations

SSAB Domex MC are cold forming steels not suited for heat treatments at temperatures above 580°C, since the material may then lose its guaranteed properties.

SSAB Domex is well suited for all common thermal and mechanical cutting processes. SSAB Domex offers good cold forming properties. Welding can be performed, using all common methods and consumables.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the products.