Advanced- and ultra-high-strength steel material - fast track from Gothenburg

Uniqueness comes from quick access to a wide selection of trial materials. Deliveries are very fast – typically only 1-3 weeks, which makes it easier for customers to test and try out new production methods thus accelerating their own product’s time to market.

“For example our automotive customers have a constant need to develop lighter and thinner solutions or find reinforcements to absorb impact energy making their vehicles safer. Their deadlines are tight – so they really appreciate if they don’t have to wait for the trial materials for months.” says Søren Madsen Automotive Global Key Account Manager.

Originally TMS catered purely to the automotive industry, but now it serves almost every business segment of SSAB. So also for example customers with construction projects can test different types of advanced high-strength and ultra-high strength steels (AHSS and UHSS) during their processes. The same applies for heavy equipment components.

TMS makes it possible for the customer not to have to order a full size coil and wait for delivery from the large mills. So the question is both of time but also of availability in smaller volumes.

“TMS is extremely important for SSAB because it gives our customers the possibility to test our steels before they put this into ’real production’. Internal orders from stock will be processed and dispatched within 2-3 days. Orders that have to be manufactured in the production line will be dispatched within 1-2 weeks”, says Madsen. TMS has been operating since 2004 and has been located in Gothenburg since 2010.

What is in stock?

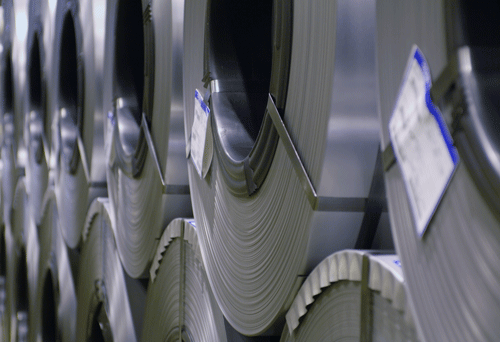

Steel grades at the Trial Material Stock include cold-rolled, cold-rolled electro-galvanized, metal coated and hot-rolled pickled steels. Sheets range from A4 (letter size) to 4 meters (13.1 feet). Slit material come in widths of 9 mm and wider and coils range from one metric ton to full size. Almost all materials are produced from coils, so the customer gets needed shape and form.

Watch the video: https://www.youtube.com/watch?v=t8TKMhDXdsA

Attachments

Category and tags