Updated end-of-driving criteria

End-of-driving criteria ensures sufficient resistances and undamaged piles

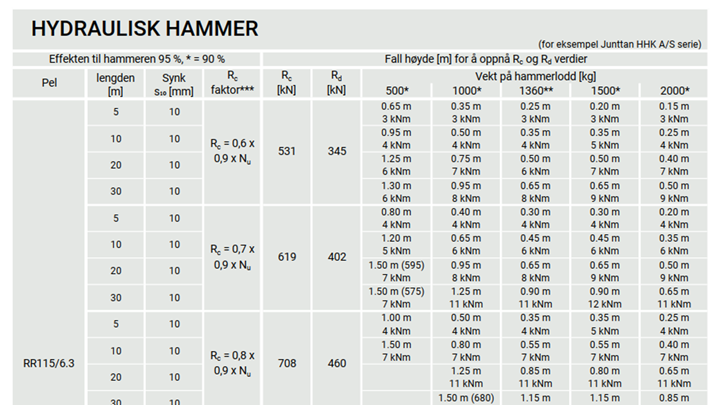

End-of-driving criteria tables are used for defining correct drop height and/or impact energy to achieve required resistance for the pile. By using the given drop heights and impact energies the piling rig operator can also ensure not exceeding the maximum allowed stress level in pile during installation. The execution standard EN 12699 for displacement piles limits the allowed stress level in steel piles for 90% of the yield strength of the pile material. By using the given table values this stress level is not exceeded.

Tables available also for Norway

Now the end-of-driving criteria tables and curves are also available for Norway. In tables the factor between ultimate geotechnical resistance value Rc and design resistance value Rd has been set to be in line with Norwegian piling guide Peleveiledningen 2019.

The total factor is a result of three components. Partial factor γb for end bearing resistance of driven piles is 1.10 (PV2019, Table 1-6), the correlation coefficient ξ5 for dynamic testing is 1.40 (PV2019, Table 1-5) and the model factor for WEAP analysis according to PV2019 is 1.0. The total factor is 1.10 x 1.40 x 1.00 = 1.54.

The tables have five different levels for Rc and Rd values. The highest level has the maximum possible Rc value with stress level 90% of the yield strength of the steel. That is the maximum allowed stress for the pile during driving, when the stress levels are not monitored, and therefore the maximum force in the pile during driving is based on that. Other levels have lower Rc values and the maximum value has been decreased with factors 0.9, 0.8, 0.7 and 0.6.

Figure 1. An example of a table for hydraulic hammers with Norwegian norms and language.

New hammers and more precise criteria

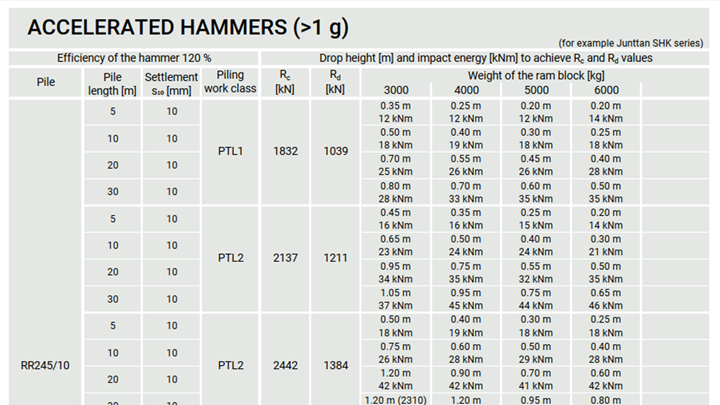

Beside drop hammers and hydraulic hammers, the updated tables include now also accelerated hammers. With accelerated hammers the efficiency of the hammers is clearly higher than with drop hammers and hydraulic hammers. The dropping of the ram block is accelerated with hydraulics to achieve higher acceleration than just gravity would give. With these hammers the efficiency has been set to 1.20.

Traditionally the end-of-driving criteria has been given as a drop height for the ram block. The new versions of the tables include also the impact energy. This is very useful for modern piling rigs where the impact energy is measured and the piling rig operator can adjust the pile driving based on an actual measured energy value.

Figure 2. Example of an end-of-driving criteria table for accelerated hammers, tables contain now both drop height and impact energy values.

New hydraulic ram

The end-of-driving criteria for hydraulic rams include now also Brokk BHB 705 breaker. The ram is capable for installing smallest pile sizes RR75, RR90 and RR115/6.3.

New versions of the tables can be downloaded from SSAB web pages:

Finnish version to Finland here

English version to Finland here

Norwegian version to Norway here

More information on RR® and RD® piles and RD® pile wall www.ssab.com/infra

Attachments

Category and tags