SSAB High strength steel piles to reduce CO2 emissions

Steel piles made of higher steel grades offer very effective way to reduce CO2 emissions in piling. For example replacing of S460MH steel grade with S550J2H steel grade or replacing of S355J2H steel grade with S440J2H steel grade have clear influence on the CO2 emissions and therefore also on the sustainability of the building project.

The CO2 emissions within steel piling can easily be reduced by using higher steel grades. Changing of steel piles made of normal strength steel to steel piles made of higher steel strengths enables the use of smaller pile sizes or the use of higher loads for similar pile sizes. Since the CO2 emissions of steel are directly related to weight of steel, this reduction of material naturally lowers the CO2 emissions.

As addition to savings on the material itself, the use of steel piles with lighter weight also gives CO2 savings in transportation and in installation phase.

Micropiles

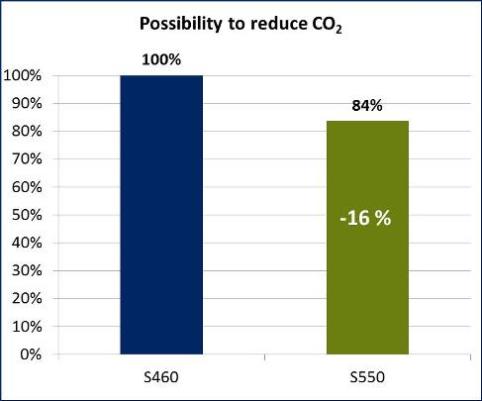

Standard steel grade for micropiles in Nordic countries is S460MH. Since the resistance of steel piles is mainly based on strength of steel, the reduction possibility goes directly in line with the increase of steel strength. If steel grade of micropiles is upgraded from S460MH to S550J2H, the possibility to reduce CO2 emissions is up to 16 %.

In addition to reduced weight and material in piles, there will be significant reduction also in transportation. If higher loads can be utilized efficiently and amount of piles needed can be reduced directly, the amount of needed piles will also be reduced by 16 %. This naturally means 16 % less CO2 emissions also in transportation.

Large diameter piles

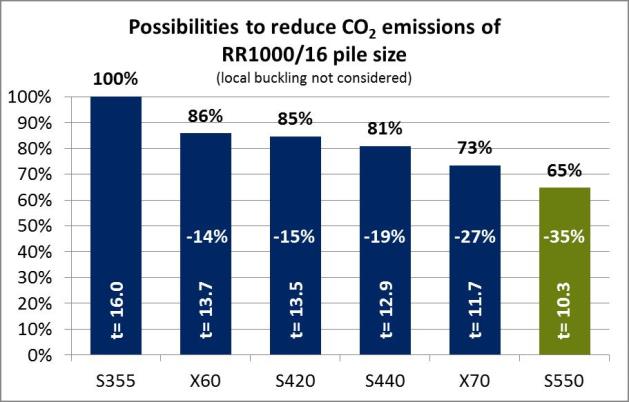

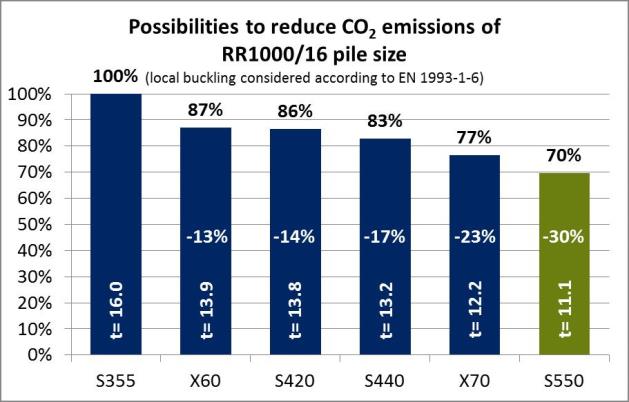

Standard steel grade for large diameter piles in Europe is S355J2H. If this most often used steel grade is replaced with steel grade S440J2H, the possibility to reduce CO2 emissions is up to 19 %.

Usually even higher steel grades are possible also for large diameter piles. For example S550J2H is available for most of the large diameter pile sizes from SSAB. If S355J2H steel grade is replaced by high strength S550J2H steel grade, the possibility to reduce CO2 emissions raises and it is up to 35 %.

With large diameter piles there is a possibility that local buckling limits the possibilities to reduce CO2 emissions by using higher steel grades. The comparison graphs below show the reduction of CO2 for RR1000/16 pile size in situations where local buckling is not considered in calculations and also in situations where local buckling is considered in calculations. The compression resistances of pile cross-sections are the same in all shown cases.

Attachments

Category and tags