The world’s northernmost RDs piles from SSAB in Longyearbyen, Svalbard

It's getting warmer and the climate is changing. On Svalbard, an archipelago situated in the Arctic Ocean, the climate change may be faster than anywhere else on earth. The annual average temperature on Svalbard can increase from -5.9 to as much as +3.3 degrees Celsius, while precipitation can increase by 40 %. Multiple avalanches have impacted Svalbard in recent years, this has resulted in the loss of 15 residential units and a shortage of private housing. Also, several government residential buildings are located in avalanche-prone zones.

Installed and ready RDs220/12,5 piles seen from NE. (Image courtesy: Thomas Mjøsund)

The project’s overall goal was to meet the need for new residences as soon as possible. This meant quick and effective processes where all of the new houses were prefab modules shipped from mainland Norway and installed on site. 60 new residential buildings making up 8.000 m2 were installed together with new roads and water mains. RDs piles together with the steel foundation framework from mainland Norway, created a solid foundation.

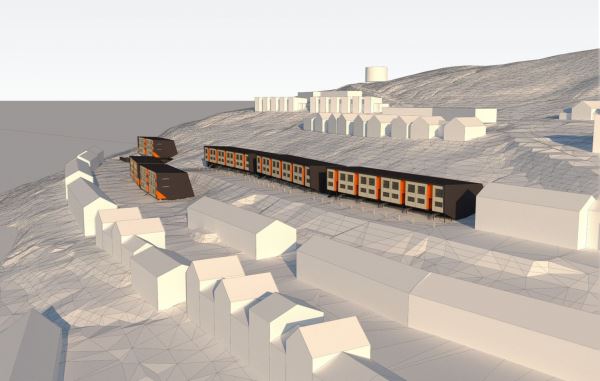

Illustration of the housing complex in Gruvedalen. (Image courtesy: LNS)

Leonhard Nilsen & Sønner AS (LNS) are the main contractors and one of North-Norway’s largest entrepreneurs specialized in demanding projects that include difficult logistics. The project was very important for LNS position in Svalbard. This has big impact on the local society and business in Svalbard. Kynningsrud Fundamentering AS acted as the piling contractor.

Gruvedalen in Longyearbyen seen from SW (Image courtesy: Thomas Mjøsund)

The main principle for building in permafrost areas is to avoid disturbance of the ground temperature profile. Due to changes in climate an increase in ground temperatures is expected. This leads to a thicker active layer, lower load-bearing capacity and increased settlement rates. That requires longer piles with larger diameter. End bearing RD piles drilled into the bedrock is a good solution for this. The foundations must have a sufficient depth to ensure that the active layer remains above the foundation throughout the life cycle of the building.

SSAB delivered close to 250 tons of RDs220/12.5 in 3 m lengths to Kynningsrud Fundamentering AS and LNS. All piles were delivered with threaded splices to avoid welding at site and to speed up the installation of over 3 800 m of piles. Summer temperatures at only 7 degrees, wind and rain created a tough working site. The most critical part of the delivery from SSAB was to get 11 trucks from Finland to Tromsø before the boat departure. If the boat was missed, it meant 2 weeks of delay at the site. Steel beams were welded into SSAB’s bearing plates acting as support for the prefab modules. Thanks to the use of SSAB’s S550J2H steel quality the piles load bearing capacity is significant increased compared to conventional steel quality.

Project manager, Thomas Mjøsund from Kynningsrud Fundamentering AS was exclusively positive with SSAB’s delivery of RDs piles with threaded splices.

RDs220712.5 piles with steel beam frame. Behind is the new water main and in front the new road. (Image courtesy: Thomas Mjøsund)

Source: statsbygg.no

Attachments

Category and tags