Upgrade with high-strength steel – Recent case in Finland shows 60 000 € savings when replacing with RRs piles

There are great possibilities to reduce costs with right decisions at the project design phase, when large part of the total project costs are determined. Upgrading to RRs pile range and high-strength S550J2H steel grade, higher load-bearing capacity and lower costs can be achieved. One recent case in Kiiruun school, Somero, showed again how there is usually a possibility to reduce the material costs by utilizing higher steel grade in piles. In this case by replacing all originally designed steel piles in standard piling steel grade, appr. 14 km, with SSAB’s high strength RRs piles, the customer saved up to 60 000 € in piling.

Figure 1. Piling of RRs piles took place in May in Somero, Finland

Using a high-strength steel grade is also an environmentally friendly solution. In construction of the foundation, the total energy requirement is reduced when strong steel’s benefits are utilized. When a stronger steel grade is used in piles, the environmental impact of manufacturing, processing, transport, and installation of the piles is reduced.

Cost savings of 60 000 € in Kiiruun school, Somero, Finland

Somero is a small municipality at the South Western Finland with only 9 000 inhabitants. Old Kiiruun school was demolished due to health issues. The old building had several problems with moisture and mold, which caused allergic reactions to students.

Figure 2. Kiiruun school is located in Somero, Finland

The soil conditions at the site are demanding. Thickness of very soft clay layer is about 25 meters. Below clay there is a sand layer and a moraine layer. Piles were embedded all the way down to the moraine layer to ensure sufficient bearing capacity. The length of the piles was varying from 29 to 35 meters.

Due to increase of pore water pressure in soil, the geotechnical designer had abandoned the use of larger driven concrete piles. Piling was designed for traditional RR piles made of S440J2H steel grade. Original design consisted of three pile dimensions; RR140/8, RR140/10 and RR170/10. Total amount of piles was 461 pile points and approximately 14 km by length.

During tendering process the piling contractor asked SSAB Infra to check if RRs piles with S550J2H steel grade could be used in this project. Technical support checked through the geotechnical and structural designs and made alternative calculations for RRs piles. In the alternative solution the amount of pile points remained the same to prevent extensive changes to other foundation designs. Also the total amount of piles by length remained approximately the same. The change was made for pile dimensions. Pile types used in alternative solution were; RRs115/8, RRs140/8 and RRs140/10.With smaller pile sizes the save of steel material was about 84 tons. This material saving together with savings from pile accessories (like pile shoe and bearing plate) resulted total saving of 60 000 € for the municipality.

“Piling work at the site became easier and faster due to the smaller dimension of the piles. Also the original pile size RR170/10 would have been too large for our current piling machinery”, says Toni Sillanpää, representative of the piling contractor Auranmaan Teräspaaluttajat Oy. He continues “Handling of the piles became easier because the bundles are clearly lighter”. Piling contractor has been satisfied with SSAB’s RRs piles in general. “We always offer with RRs piles in larger projects. If the project is very small, the benefits of the alternative solution might be lost in the amount of work due to the change. The alternative solution must be accepted by the main contractor and the designer.”

Figure 3. Piling work at the site was easier and faster due to the smaller dimension of the piles

Higher load-bearing capacity and lower costs with RRs pile range and high strength S550J2H steel grade

The excellent properties of the RR piles, such as easy and quick splicing with an external friction splice as well as other pile accessories, are utilized also in RRs piles manufactured of high-strength steel. Advantages of the high-strength steel S550J2H in SSAB’s RRs piles:

- a cost-efficient foundation structure solution for a wide range of building projects

- less displacement and disturbance of soil in relation to the load-bearing capacity of the pile

- reduced vibration in relation to the load-bearing capacity of the pile

- ability to use lighter installation equipment

- ease of installation

By using the higher steel grade S550J2H, pile’s load-bearing capacity can be added by 25 % over that of traditional RR piles. The increased load-bearing capacity of the pile can be utilized by decreasing the number of piles.

Alternatively, a RRs pile made of high strength steel can replace a RR pile with bigger size. Good example of this is the new RRs220/10 pile size, which can easily replace pile size RR220/12.5.

Availability of RRs piles

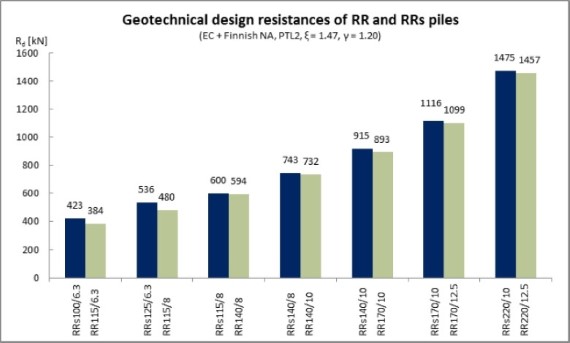

There are already several RRs pile sizes available to replace RR piles. In the last newsletter we introduced a new member to the RRs pile selection: RRs220/10. All available pile sizes are presented in figures 4 and 5 below. The use of high-strength steel piles has been growing and widening of the selection answers to those needs. In figure 4 the geotechnical resistances of standard RR piles are shown in green columns. The geotechnical resistances of the RRs piles suitable for replacing the RR piles are shown in blue columns.

Figure 4. Geotechnical design resistances for certain RR and RRs piles

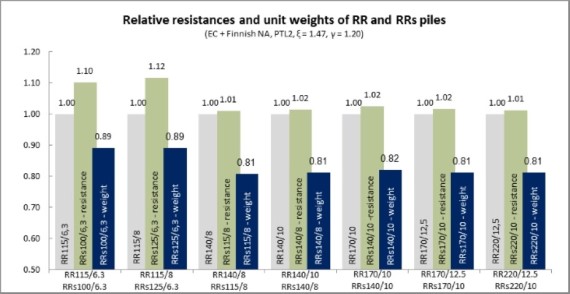

The columns in figure 5 represent relative geotechnical design resistances and relative weights per meter of RR and RRs piles. In figure the relative values of RR piles are represented with value 1.00.

Figure 5. Relative geotechnical design resistances and relative weights per meter for certain RR and RRs piles

Attachments

Category and tags