SSAB’s Toijala Works delivers cold-formed section components for Metsä Group’s automated storage facility shelving at bioproduct mill

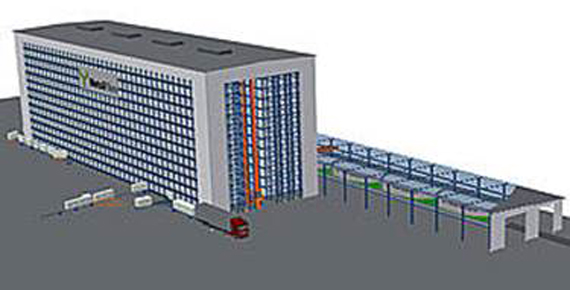

The automated pulp distribution center is the first of its kind in the world. When the bioproduct mill enters production in the third quarter of 2017, the entire annual production of 1.3 million tonnes of pulp will be taken to the distribution center. The distribution center will be an integrated part of the entire logistics chain: it will buffer, sort and divide the product for various transportation and control all dispatch operations from the mill to the customer. SSAB’s shelving at the pulp bale distribution center will also serve as the frame of the building, which will be 100 meters long, 25 meters wide and 30 meters high. One bale of pulp weighs about 3 tonnes.

The cold-formed section components to be delivered to the customer have been made largely from SSAB’s galvanized steel strip, which has been perforated, roll formed and cut to size at SSAB’s Toijala Works. Close cooperation with the customer at the design stage also employed SSAB’s technical customer service. Toijala will deliver around 1,300 tonnes of cold-formed section components for the project. There are a total of seven different cross-sections and the cold-formed sections vary in length from 400 millimeters to 10 meters.

“Delivery logistics from Toijala will be flexible and cost efficient since our component assembly site in Finland is quite close. Component deliveries will take place in stages between weeks 25 and 40,” says Harri Peltomaa, Director, Production and Sourcing at Pesmel Oy.

“The cold-formed sections from the Toijala Works are ideal for use in the structures of an automated warehouse. Our flexible, all-round production lines enable the dimensionally accurate perforation of cold-formed sections, which in turn speeds up installation work at the final site,” said Hannu Koukkari, site manager of SSAB’s Toijala Works.

For more information, please contact Hannu Koukkari, Site manager, SSAB Toijala Works, tel. +358 20 592 8223