RDT loose sleeve splice product range extended

Loose sleeve splice concept of RDT piles has now extended to RDT270 and RDT320 pile sizes. Splices for both pile sizes have now been tested and are ready for use. ETA assessment will be acquired for both new splices and after that they will have CE mark. However this process takes some time and during this period there will be a statement available from Notified Body to prove the validity of the splices.

RDT splices have new type of threads which SSAB introduced in 2018. New thread profile makes tightening of threads easier and faster. Experiences of new threads have been very positive at the sites.

For availability and delivery, please contact SSAB sales.

Testing of new splices

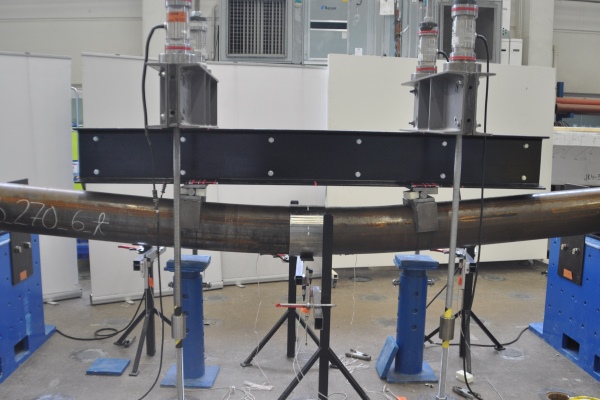

Splices were tested for steel grades up to S550J2H and they clearly passed all the tests. Tests were done at Tampere University and followed by personnel from Eurofins Expert Services Oy, a notified body for construction products in Finland.

Figure 1. RDTs270/12.5 pile in bending test at Tampere University

Figure 2. RDTs320/12.5 piles after bending test

Since splices have same resistance as the pile pipe itself, the designer doesn’t need to consider splices in design. The structural resistance of spliced pile is the same as resistance of non-spliced piles’.

Available RD® piles with RDT loose sleeve splices

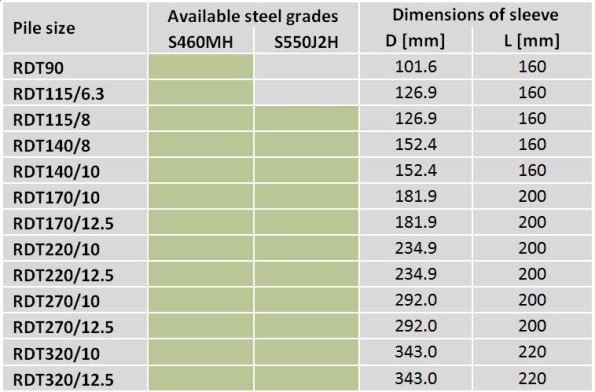

Since RDT270 and RDT320 have now also threaded RDT loose sleeve splice, the availability of different pile sizes and steel grades has widened. Available RDT pile sizes, steel grades and also the diameters of the splice sleeves are shown in Table 1 below.

Table 1. Availability of RDT splices and dimensions of RDT sleeves

More information on RD piles: RR and RD piles Design and installation manual www.ssab.com/infra

Załączniki

Kategorie i tagi