HDPE coated piles for renovation of sheet piled quay wall in West Harbour

West Harbour is located at Jätkäsaari, where construction of Helsinki’s new maritime district is progressing at full speed. Jätkäsaari is gradually being transformed into a district offering residential areas, workplaces and services. The shore area of Jätkäsaari was previously used for industrial and harbour purposes.

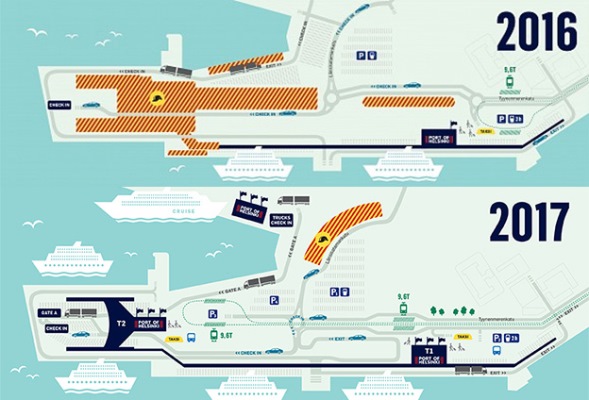

The Port of Helsinki is developing West Harbour and building a new terminal area at the tip of Jätkäsaari, where the new West Terminal 2 is due for completion in spring 2017. The new passenger pavilion will, together with the old West Terminal 1, provide a smooth travel experience for the millions of passengers travelling between Helsinki and Tallinn each year. The route across the sea between the cities is one of the busiest in the world, and its passenger numbers are growing constantly.

Figure 1. West harbour maps in 2016 and 2017.

SSAB has delivered steel piles for the quay structures in Ferry berth LJ6. Main contractor of the project was Suomen Vesityö Oy and the designer has been FCG Oy. Piling work has been done by Kantolan Paalutus Oy. Quay structures consist of sheet pile wall which is supported by steel piles. Larssen 605K sheet piles are 15 - 16 meter long and include protective painting in the upper part with length 5,0 m. There are in total 52 RR450/12.5 piles. Steel grade is S355J2H. Pipe piles are made of two parts. Lower parts of piles are 18-19 meters long and upper parts are 12 meters long. Upper parts are protected with HDPE coating. Piles are equipped with rock shoes.

Figure 2. Installation of sheet piles.

Construction work started with pulling up the sheet piles of the existing quay structure. The old erosion plate (thickness 0.5 m, width 10.0 m) in the bottom was demolished without problems. After that new sheet piles were installed, RR450 pipe piles were pile was driven in every third of the sheet pile channels. When all sheet piles and RR450 piles were installed, they were cut from the designed level. After that the capping beam could be cast. The work was completed successfully in spite of very small workspace and existing ship and ferry traffic.

Figure 3. RR piles supporting sheet pile wall in ferry berth LJ6.

Figure 4. All sheet piles and RR450 piles installed and structure is ready for capping beam casting.

Figure 5. All sheet piles and RR450 piles installed.

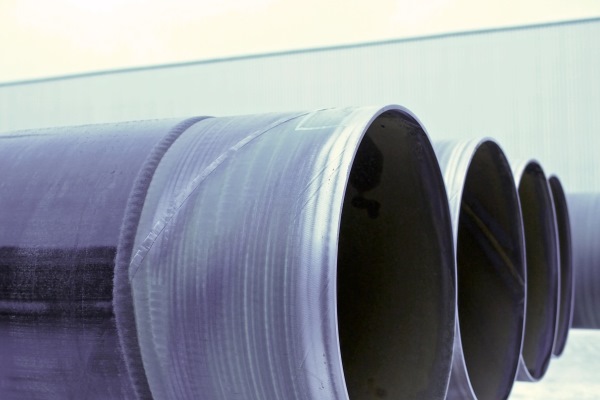

Piles were delivered with HDPE (High Density Polyethene) coating to protect the piles against corrosion and mechanical stress caused by ice conditions and propeller slipstream. The 3-layer coating consists of epoxy, adhesion and polyethylene, layers. HDPE coating is done at SSAB’s Oulainen works. Piles (L= 10-18 m) are coated over the full length at the same time. Coating is removed from the end of the pile to enable welding of the pile.

In this project it was proven again that HDPE coating stands very well handling and installation of piles without damages to the coating surface. HDPE coated piles were used the first time in the renovation of West harbor’s quay structures already in 2007. The experience during the ten years has been very good.

Figure 6. HDPE coated piles waiting for transportation at SSAB’s Oulainen works.

Renovation of the quay structures in Ferry berth LJ6 will continue during summer 2017. Quay structure consisting of sheet pile wall supported by steel piles as well as the installation principle will remain the same .

Załączniki

Kategorie i tagi