New RRs220/12.5 pile size has been tested and it fulfills all the requirements – CE marking will follow

All SSAB’s piling products go through a comprehensive testing before they are approved and CE marked. New RRs220/12.5 pile size has been tested on site and in laboratory. Guidelines for testing methods and requirement levels are presented in EAD (European Assessment Document) for steel pipe piles. Additionally there are also some national requirements for performance levels, which need to be fulfilled.

Most important thing is to test how strong and rigid mechanical pile splices are. Tests for splices start with robustness test. For driven piles this means impact blow tests on site. After impact blow tests the test piles are taken to laboratory for bending, tension and compression tests. For threaded splices used in drilled RD piles the robustness test means tightening test in laboratory.

Figure 1. EAD for steel pipe piles

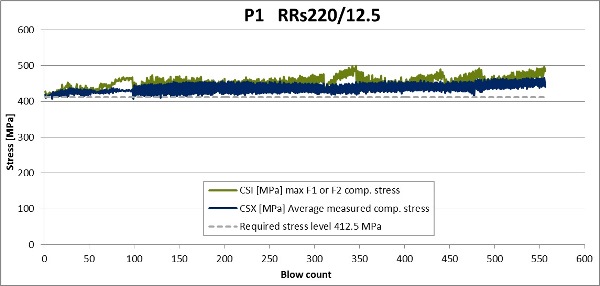

Impact blow test

Testing is done on site with piling rig. Usually drop hammer or hydraulic hammer is used, but also hydraulic ram can be used for smaller pile sizes. Test piles with splice are first driven to contact with bedrock surface. After contact has been reached, strain transducers are attached to pile to measure stress level in pile during testing. Usually PDA equipment is used to measure and store the data.

According to EAD the number of blows needs to be at least 200 with drop hammer or hydraulic hammer and 2000 with hydraulic ram. The stress level needs to be at least 0.5 x yield strength of the pile pipe.

In Finnish national requirement the number of blows is at least 500 with drop hammer or hydraulic hammer. If tested pile size is meant to be used also in most demanding piling works (Piling Work Class 3 – PTL3), the stress level needs to be at least 0.75 x yield strength of the pile pipe.

All SSAB’s piles are tested to meet more demanding requirements than given in EAD to fulfill Finnish national requirements for the most demanding piling works.

Figure 2. Impact blow tests for RRs220/12.5 pile size with 4 ton hydraulic hammer

Figure 3. Measured stress levels for RRs220/12.5 test pile number P1 during impact blow tests

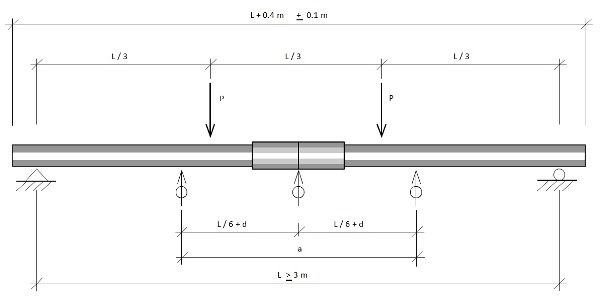

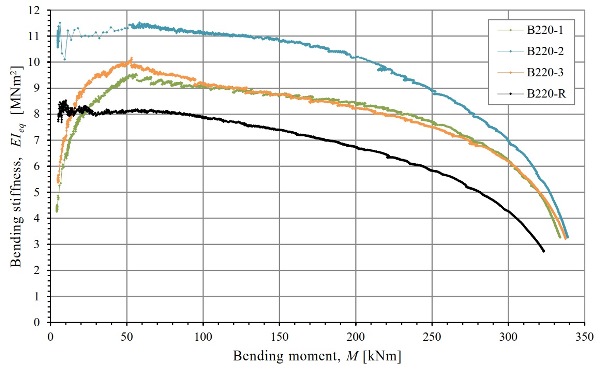

Bending test

Bending test is used for testing the bending resistance and bending stiffness of the pile splice. Bending test is done in laboratory according to EAD and some national guides.

Figure 4. Assembly drawing of a bending test (Finnish Piling Guide PO-2011)

Bending resistance of the pile with splice needs to be at least the same as bending resistance of similar pile without splice. The bending stiffness of the pile with splice needs to be at least 0.75 x bending stiffness of similar pile without splice in moment range 0.3 – 0.8 x M.

Figure 5. Bending test for RRs220/12.5 test pile number B220-3

Figure 6. Bending stiffness results for RRs220/12.5 pile, sample B220-R is a reference pile pipe

Tension test

Tension test verifies installation capability of the splice. During installation pile faces also tension stresses and therefore also pile splice needs to withstand some amount of tension.

The requirement for the tension resistance is at least 0.15 x tension resistance of similar pile without splice.

Figure 7. Tension test for RRs220/12.5 test pile number T220-1

Compression test

Compression test is not required if pile pipes to be spliced are supported on each other in the whole cross section area and pile splice fulfills the above mentioned requirements for robustness, bending and tension. Compression test is needed for example when testing threaded splices for RD and RDs piles.

Figure 8. Compression test for RD140/10 with threaded splice (KTH test report)

Załączniki

Kategorie i tagi