Mechanical Properties

(min MPaksi)

(min MPaksi)

(MPaksi)

(min %)

(x t)

1) For both longitudinal and transverse direction.

The mechanical properties are tested in the longitudinal direction.

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(min %)

(max %)

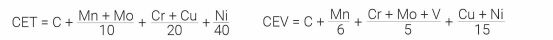

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Strenx® Thickness Guarantees.

Strenx® Thickness guarantees meet the normal thickness tolerance requirements of EN 10131.

Length and Width

Tolerances according to EN 10131.

Narrower tolerances according to the SSAB standard are available on request.

Length tolerances only apply for cut to length sheets.

Flatness

Tolerances according to Strenx® Flatness Guarantees Class B.

Strenx® Flatness Guarantees offer narrower tolerances compared to EN 10131.

Flatness guarantees only apply for cut to length sheets.

Delivery Conditions

Cold rolled. Strenx® Cold rolled products are available with mill or cut edge.

Fabrication and Other Recommendations

Welding, bending and machining

Strenx® Cold rolled products has good cold forming, welding and cutting performance.

Strenx® Cold rolled products is not suited for applications requiring hot working or heat treatments at temperatures above 180°C, since the material then may lose its guaranteed properties.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the products.

Strenx® 700 CR high-strength structural steel

Strenx® 700 CR is a cold-rolled high-strength structural steel with a minimum yield strength of 700 MPa. This steel is used to produce a wide range of strong and light equipment. Strenx® 700 CR is covered by the Strenx® guarantees for flatness, thickness and bending properties, ensuring predictable performance in the workshop. The steel is available as thin sheets or coils with thicknesses between 0.7 and 2.1 mm, width up to 1500 mm and cut-to-length sheets up to 8500 mm.

Get technical adviceShow specs in:

Build it with 37% higher strength

By upgrading from Strenx® 700 CR to Strenx® 960 CR, you gain 37% higher yield strength. This gives you opportunities to redesign your equipment for increased performance and reduced weight. Get in touch with our steel specialists at SSAB Tech Support or SSAB Knowledge Service Center for an update on upgrading.