Hardox® HiTemp

Hardox®HiTemp is a high-heat grade of Hardox® wear plate. It provides a cost-efficient solution for wear resistance at high temperatures up to 500°C (930°F) with a nominal hardness of 400 HBW. When traditional quenched and tempered wear-resistant steels lose hardness at higher temperatures, Hardox® HiTemp steel still delivers high wear resistance.

A high temp metal that can take the heat

If you need to build heavy equipment that can fight wear in tough, high-temperature applications, take a look at Hardox® HiTemp wear resistant steel. While traditional Q&T wear-resistant steels experience a loss of hardness at temperatures of 300-500°C (about 570-930°F), this high temp metal stays strong and hard to improve performance and extend the service life of costly equipment.

The outstanding performance of this heat resistant material is achieved by using high-quality raw material combined with a carefully controlled manufacturing process. And in your workshop, Hardox® HiTemp can be cut, welded, machined and cold formed using the same kind of machinery as other Hardox® grades and conventional AR steel.

I’m interested, contact me

A heat resistant material for a wide variety of uses

Abrasive and hot materials like slag – leftover waste from metal smelting or refining with a highly angular shape and rough surface texture – are no match for high-temperature, high-strength Hardox® HiTemp in truck bodies. With a redesigned body using a thinner plate in the body’s flooring and sides, you can get more payload when the truck is fully loaded. Plus, the thinner plate lowers the overall weight of the truck when it travels empty.

In coking plant equipment, Hardox® HiTemp provides a cost-effective, long-lasting solution in coke ramps, quenching wagons, cooling beds, slag tippers, furnace inlet scrapers and other heat-affected equipment. In short, Hardox® HiTemp makes a great choice wherever you need optimal wear resistance and high structural strength.

Get free technical advice

Altus extends service life by years with slag dumper bodies in Hardox® HiTemp

Altus in Singapore saved 40% weight or 2.236 kg (4,930 lbs) by switching from 25 mm (0.984”) mild steel to 10 mm (0.394”) Hardox® HiTemp in the slag dumper’s floor and from 12.7 (0.5”) to 10 mm (0.394”) in the sides.

How Altus increased service life with Hardox® HiTemp

Hardox® HiTemp reduces maintenance intervals from months to years in coke plant

When hit by 1.000 °C (1.832°F) coke, Hardox® HiTemp is up to the challenge. By replacing ceramic tiles, which are costly and prone to cracking, with steel plates of Hardox® HiTemp, SSAB Oxelösund in Sweden could reduce maintenance costs drastically and create a safer working environment.

How SSAB slashed maintenance costs in its coke plantOne of the best steels for high temperature applications

Hardox® HiTemp is one of the best steels for high temperature applications involving moderate wear, especially in process industries like steel, cement, asphalt, coal power or recycling. Applications for this high temp metal include:

- Dryer drums and lifter plates inside dryers in asphalt plants

- Clinker cooler plates and other liner plates in cement plants

- Blast furnace components and slag buckets in steel plants

- Rotary seal valves in coking plants

- Liner plates, ash handling equipment and chain conveyers in power plants

- Scrapers, screeners and liner plates in foundries

- Liner plates, gypsum and clinker hammers in crushers

Heat resistant ceramics vs. our high temperature steel

Hardox® HiTemp can provide advantages over other materials like heat resistant ceramics or mild steel. For example, coke ramps made in thick basalt ceramic tiles are incredibly expensive, plus prone to cracking. This means more maintenance stops and money-wasting downtime. But with Hardox® HiTemp, you get a wear resistant steel that weighs less, yet stays strong and lasts long. And because of its workshop-friendly properties, you’ll have a quick and easy installation compared with materials like heat resistant ceramics that are common in high-temperature environments.

Benefits of Hardox® HiTemp high temp metal

- Can withstand the deformation that leads to buckling and cracks at high temperatures

- With high-strength steel in thinner plates, you can lower product weight while maintaining strength and durability to prolong service life

- Since it has a low carbon equivalent, it can be thermally cut without pre-heating within the whole dimension range – also suitable when much welding is needed

- Can be welded and cold formed using conventional methods and machinery

- Workshop-friendly properties enable quick and easy installation compared with other materials (like heat resistant ceramics) that are common in high temperature environments

- Helps to reduce costs, increase uptime and improve safety thanks to less frequent shutdowns for maintenance and repairs

Mechanical Properties

(mmin)

(HBW)

(MPaksi), not guaranteed

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface for plate. At least one test specimen per heat and 40 tons.

The nominal material thickness will not deviate more than ± 15 mm from that of the test specimen.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Impact Properties

Charpy V 10x10 mm test specimen 1)

1) Impact toughness measured upon agreement. Impact testing according to ISO EN 148 per heat and thickness group. Average of three test.

2) Typical value for 20 mm.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

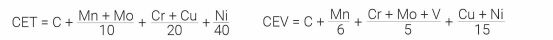

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantees.

Hardox® Guarantees meet the requirements of EN 10029 Class A, but offer more narrow tolerances.

Length and Width

According to SSAB’s dimension program.

Tolerances according to SSAB´s mill edge standards or tolerances that conform to EN 10029.

Shape

Tolerances according to EN 10029.

Flatness

Tolerances according to Hardox® Flatness Guarantees Class C, which are more restrictive than EN 10029 class N.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched. The plates are delivered with sheared or thermally cut edges. Untrimmed edges after agreement.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Bendability according to Hardox® Bending Guarantees Class E.

Hardox® HiTemp is not intended for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 500oC.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.