Hardox® 600

Hardox® 600, with a nominal hardness of 600 HBW, is an extra-hard wear resistant steel that can be cut and welded. It is designed for use in high-performing wear parts in harsh wear environments.

Hardox® 600 for superior wear resistance

With Hardox® 600, you don’t have to sacrifice wear resistance for impact strength. Thanks to its properties, this steel can withstand impacts that often lead to fracture or destruction of other wear parts made in white iron chromium castings, manganese castings, bimetals or ceramics. Hardox® 600 has an impact toughness that can make it more durable than those materials. It also successfully fights sliding wear. Want to learn if Hardox® 600 is right for your particular application?

I’m interested, contact me

Why Hardox® 600?

- Makes a good alternative to conventional AR steel or Hardox® steel with lower hardness grades, manganese steel castings or ceramics

- Parts made with this high-strength and hard steel are strong and durable

- Get thinner yet higher-performing wear liner packages

- A long and predictable service life leads to lower maintenance costs and increases productivity

- Long-lasting and productive equipment has environmental benefits, since it uses less steel and energy over time

- Widely available plates, shorter delivery time compared to manganese steel castings

- Workshop benefits: Comes already through-hardened, is machineable and weldable, standard workshop methods can be used

- Spare parts can be quickly and easily fabricated

Typical applications for Hardox® 600

- Mining, quarrying and earthmoving utilize Hardox® 600 for wear liners exposed to sliding wear, chute liners, conveyor skirt boards, screens, silo and pan feeder liners.

- Hardox® 600 is used for industrial process equipment such as crusher knives, hammers, discs, blades, jaw crusher cheek plates, liner plates, deflector plates, shredder knives, cone crushers, ball mill liners, concrete molds, vertical and horizontal shaft impactor discs and liners, and knives for flaker rings.

- Cement, concrete, steel and energy plants use chutes, hopper liners, vertical rolling mill liners, feeder liners and screens, baffle plates, split scrapers and guide vanes in Hardox® 600.

- Forestry equipment in Hardox® 600 is for example harvester feed rollers, log washer paddles and shredder knives.

Extra-hard steel that works longer for your equipment

A little extra hardness can go a long way. At the high end on the hardness scale for our Hardox® range of grades, Hardox® 600 can give your equipment the extra edge in service life in applications that take a beating. Hardox® 600 has a yield strength around 1650 MPa, much higher than for standard structural steels like S355 steel, which has a yield strength of about 355 MPa.

If you upgrade from a lower Hardox® grade like Hardox® 500, you can gain up to a 50% longer equipment service life. When upgrading from a 400 HBW AR steel, you can get a service life up to 4 times longer. If you do opt for using a lower-grade material, remember that you might be looking at higher production, replacement and downtime costs in the long run.

Explore a selection of Hardox® 600 applications

Prismatic knives

Used in recycling plastic, electronic waste and aluminium, prismatic knives in Hardox® 600 will extend service life. The toughness of Hardox® 600 will reduce the risk for chipping compared to tool steel, providing a more reliable solution.

Floor lining in planetary mixers

The high hardness of Hardox® 600 offers very high wear resistance in combination with the possibility to drill, countersink or even stud weld bolts to the steel. This makes Hardox® 600 an easy solution compared to HCWI casted material or chromium carbide solutions.

Concrete brick molds

Concrete molds for concrete or terracotta pavers made of Hardox® 600 extend service life many times compared to the previous 500 HBW steel. Extends lifetime from 4-8 weeks to an entire 6-12 months.

Transfer chutes

A transfer chute with liner plates in Hardox® 600 provides a long service life when moving iron ore and other highly abrasive materials. Compared to an AR 500 steel, Hardox® 600 can double the lifetime.

.jpg%3Fm%3D20231116135440&w=3840&q=75)

Mining equipment gets tough on downtime with Hardox® 600

Learn how mining and materials company LKAB benefits from the superior wear resistance of Hardox® 600.

Calculate wear life with WearCalc

With the Hardox® WearCalc app from SSAB, you can determine the increase in service life of equipment for different Hardox® grades compared to mild steel. Calculations include a lot of abrasive materials such as granite, clinker, coal, iron ore, limestone, sand, glass and household waste containing metal.

Get the WearCalc app

Dimension Range

Hardox® 600 is available as plate in thicknesses of 6.0 – 65.0 mm and as sheet in thicknesses of 3.0 - 6.0 mm. Hardox® 600 is available in widths up to 2000 mm and lengths up to 14630 mm. Preferred dimensions for the plates are 2000 x 4000 mm. For sheets in thicknesses of 3.0 - 4.5 mm the preferred dimensions are 1250 x 3000, and for sheets in thicknesses between 4.5 - 6.0 mm the preferred dimensions are 1500 x 3000 mm. Other dimensions on request. More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

(mmin)

(HBW)

(mmin)

(HBW)

(mmin)

(HBW)

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons. The nominal thickness of supplied plates will not deviate more than +/- 15 mm from the thickness of the test specimen used for hardness testing. For sheet the Brinell hardness test is according to EN ISO 6506-1 on each heat treatment individual/coil. Hardness is measured on a milled surface 0.3 - 2 mm below surface.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

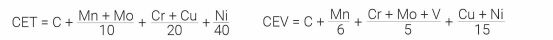

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantee.

Hardox® Guarantees meet the requirements of EN 10029 Class A for plate, but offer more narrow tolerances. For sheets the guarantees meets the requirements of 1/2 EN 10051.

Length and Width

According to SSAB’s dimensions program. Tolerances conforms to EN 10029 or to SSAB’s standard after agreement. For sheet the tolerances are according to EN 10051 or to SSAB´s standard after agreement.

Shape

Tolerances according to EN 10029 for plate and according to EN 10051 for sheet.

Flatness

Tolerances according to Hardox® Flatness Guarantee class D, which are more restrictive than EN 10029 Class N. For sheet, the tolerances are according to Hardox® Flatness Guarantees Class B, which are more restrictive than EN 10051.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched or Quenched and Tempered. Plates are delivered with sheared or thermally cut edges and thicknesses over 80 mm are delivered with mill edge as standard. Sheets are delivered with an as-rolled surface and mill edge as standard.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Hardox® 600 is not intended for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 250ºC for plate and 150ºC for sheets.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.