.jpg%3Fm%3D20230412132037&w=3840&q=75)

Hardox® 450

Hardox® 450 is probably the world’s most recognized wear-resistant steel, with tight tolerances and excellent structural properties, only from SSAB. With a nominal hardness of 450 HBW, Hardox® 450 combines good bendability and excellent weldability. The extra 50 HBW hardness over our Hardox® 400 grade provides better dent and abrasion resistance as well as longer wear life. Or you can use the additional hardness to reduce plate thickness and get lighter equipment.

What is Hardox® 450?

Hardox® 450 has been setting the benchmark for quality steel for more than 30 years, for good reason. It has a solid reputation as a highly versatile, abrasion-resistant steel that also has structural properties. With an extra 50 HBW hardness over AR 400 grades, it provides additional wear resistance for an extended service life with similar toughness as an AR 400 steel. This allows for more high-performing buckets, dump bodies and other equipment that lasts longer and still can take impact forces without compromising structural integrity.

I’m interested, contact me.jpg%3Fm%3D20230412132034&w=3840&q=75)

.jpg%3Fm%3D20230412132030&w=3840&q=75)

Hardox® 450 leaves S235 and S355 steel behind

Hardox® 450 consistently outperforms mild steel, whether it’s S235, S355, A36, grade 50, A514, SS400, S45C or any AR 400 grade. That’s why it’s the industry standard for hard-wearing, hard-working equipment. Mild steel simply doesn’t have the strength to enable modern excavators or other machines to perform at their full potential. Premature maintenance or repairs just because the business end of your equipment isn’t hard or strong enough is neither convenient nor cost-effective. When switching to Hardox® 450 from such steels, expect a more productive operation with less downtime.

Same, same, only more sustainable

Hardox® 450 made with SSAB Zero™ is a new version of Hardox® wear plate that maintains all the qualities that made Hardox® 450 the global benchmark for premium wear steel. The ultimate sustainable choice, SSAB Zero™ is produced using recycled steel in a process powered by carbon-free electricity and biogas – resulting in virtually no carbon emissions from fossil fuels. With this innovative steel, you can take your sustainability goals to the next level.

Relative service life of Hardox® 450 compared to S355 steel in sliding wear for different abrasive materials

If you want to protect the valuable investment you made in your equipment, Hardox®450 can significantly extend its service life. Here’s how Hardox® 450 outperforms milder steels like S355 and S235 when exposed to sliding wear from different abrasive materials.

Download Hardox® WearCalc and do your own calculations.jpg%3Fm%3D20230412132023&w=3840&q=75)

.jpg%3Fm%3D20230412132019&w=3840&q=75)

Hardox® 450 is more than a number

Comparing wear steels on the basis of hardness only is not enough. Hardox® 450 is different than your average AR 450 steel. It starts already in the quenching and tempering process at the steel mill, giving Hardox® 450 its guaranteed through-thickness hardness. Your advantage? Outstanding, dependable and predictable performance, throughout the service life of your equipment.

Additionally, Hardox® 450 comes with guarantees for thickness, flatness, and bending performance. These properties ensure predictable processing in the workshop. Every plate you work will behave just like the one before it. There won’t be any unexpected surprises – great news for every production manager.

Download Hardox® guaranteesReady to step up a grade from AR450?

Hardox® 450 has been state-of-the-art in wear steel for a long time, and it will stick around. That shouldn’t stop you from exploring newer grades of Hardox® steel. Hardox® 500 Tuf has taken the toughness of Hardox® 450 and added 50 HBW in extra hardness. May not sound much but the effect on wear life is impressive. Calculations with the Hardox® WearCalc app show that Hardox® 500 Tuf can increase wear life compared to Hardox® 450 by close to 50%.

Learn more about Hardox® 500 Tuf.jpg%3Fm%3D20230412132026&w=3840&q=75)

See how Hardox® 450 brings benefits to OEMs and end users

Find your closest Hardox® 450 steel supplier

Local supplies of Hardox® 450 are available anywhere in the world. In less than 48 hours, you can get the most popular Hardox® grades and dimensions from an SSAB mill or local SSAB stocks. Hardox® Wearparts, our global network of wear service centers, manufactures wear parts from Hardox® 450 and other Hardox® grades.

Find your local Hardox® 450 supplier.jpg%3Fm%3D20230412132041&w=3840&q=75)

.jpg%3Fm%3D20230412132015&w=3840&q=75)

Where is Hardox® 450 used?

If we were to list industries where Hardox® 450 isn’t used, it would be a very short list. Wear is a challenge in most industries, and Hardox® 450 has been the go-to solution to meet these challenges. Here are some machines and equipment that use Hardox® 450: Concrete mixers, snow blowers, roll-off containers, excavator and front loader buckets, grapples, shears, garbage trucks, dump trailer bodies, concrete drums, asphalt rollers, potato harvesters, recycling tools, crushers, chutes – just to mention a few.

Dimension Range

Hardox® 450 is available in thicknesses of 3.2 - 160 mm as plate, as sheet in thicknesses 2.0 - 8.0 mm and as CR sheet in thicknesses 0.8 - 2.1 mm.

Hardox® 450, made from SSAB Zero™ steel, is now available in thicknesses ranging from 4.0 to 25.4 mm. For plate thicknesses over 80 mm, the preferred width is 1650 mm. More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

(mmin)

(HBW)

(MPaksi), not guaranteed

(mmin)

(HBW)

(MPaksi), not guaranteed

(mmin)

(HBW)

(MPaksi), not guaranteed

(mmin)

(HBW)

(MPaksi), not guaranteed

(mmin)

(HBW)

(MPaksi), not guaranteed

1) Hardox® 450 made from SSAB Zero™ steel is available in thicknesses of 4.0 - 25.4 mm as plate. For more information about SSAB Zero™, please see the SSAB Zero™ section.

2) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons.

3) Hardness test is not performed or guaranteed for Hardox® products with thicknesses < 2.5 mm. The tabulated hardness values for thickness < 2.5 mm is a conversion from the tensile strength.

For more information please see the datasheet 2067- Hardness conversion of thin Hardox® wear sheet.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Impact Properties

Charpy V 10x10 mm test specimen 1)

1) Impact toughness measured upon agreement. For thicknesses between 3 mm and 11.9 mm, subsize Charpy V-specimens are used. The specified impact toughness is then proportional to the cross-sectional area of the test specimen, compared to a full-size specimen (10 x 10 mm). Impact testing according to ISO EN 148. Average of three tests.

2) Typical value for 20 mm.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

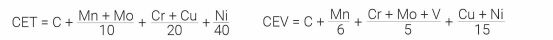

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantees. Hardox® Guarantees meet the requirements of EN 10029 Class A for plate. For sheet, the guarantees meet the requirements of ½ EN 10051 and ¾ EN 10131 for cold rolled sheet products.

Length and Width

According to SSAB’s dimension program. For plate, the tolerances are according to SSAB´s mill edge standard or tolerances that conform to EN 10029 and EN 10131 for cold rolled sheet. For sheets, the tolerances exceeds the requirements of EN 10051.

Shape

Tolerances according to EN 10029 for plate, EN 10051 for sheet and EN 10131 for cold rolled sheet

Flatness

Tolerances are according to Hardox Flatness® Guarantees Class C for plate, which are more restrictive than EN 10029. For sheet, the tolerances are according to Hardox® Flatness Guarantees Class A, that offer narrower tolerances compared to EN 10051. Cold rolled sheet tolerances are according to Hardox® Flatness Guarantees Class B.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched or Quenched and Tempered. Hardox® 450 plates are delivered with sheared or thermally cut edges, and thicknesses over 80 mm are delivered with mill edge as standard. Hardox® 450 sheets are delivered with an as-rolled surface and mill edge as standard. Hardox® 450 cold rolled sheets (0.80 - 2.10 mm) are supplied as cold rolled surface.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Bendability for plate are according to Hardox® Bending Guarantees Class E. For sheet, the bendability are according to Hardox® Bending Guarantees Class B for cold rolled sheets, and Class A for sheet.

Hardox® 450 is not intended for further heat treatment. Mechanical properties are achieved by quenching and when necessary, by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 250 oC.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.