General Product Description

SSAB Domex 460ML is a thermomechanically rolled structural steel plate that provides high strength at low temperatures. SSAB Domex 460ML meets or exceeds the requirements of S460ML in EN 10025-4.

Dimension Range

SSAB Domex 460ML is available in thicknesses of 8.00-63.00 mm and in widths up to 3300 mm depending on the thickness. More detailed dimensions are provided in the dimension program.

Mechanical Properties

(mmin)

(mmin)

(min MPa)

(MPa)

(min %)

(mmin)

(mmin)

(min MPa)

(MPa)

(min %)

(mmin)

(mmin)

(min MPa)

(MPa)

(min %)

The tensile test is made transverse to the rolling direction in compliance with EN 10025-4.

Impact Properties

Charpy V 10x10 mm test specimens

Charpy V 10x10 mm test specimens

The impact test is made longitudinally to the rolling direction in compliance with EN 10025-4.

1) For thicknesses above 50.00 mm 27J/-50°C.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(min %)

(max %)

(max %)

(max %)

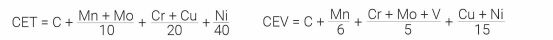

Carbon Equivalent

Tolerances

Thickness

SSAB Domex ML products are delivered with tolerances that correspond to ¾ of EN 10029 Class A as default value.

Length and Width

Width tolerances -0/+4-10 mm depending on the thickness. Length tolerances -0/+15-75 mm depending on length.

Shape

Tolerances according to EN 10029.

Flatness

Maximum flatness deviation 6 mm/m.

Surface Properties

According to EN 10163-2 Class A, Subclass 3.

Delivery Conditions

Thermomechanically rolled (M).

Fabrication and Other Recommendations

Minimum inner bending radius is 1.0 x t transverse to the rolling direction and 1.5 x t longitudinal to the rolling direction up to max 20mm in thickness.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the products.