General Product Description

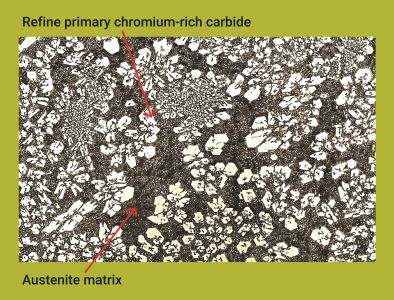

Duroxite® Roller Wire is a flux-cored welding wire for roller repair in the cement and power industries using an open-arc welding process. The weld deposit contains abrasion-resistant material which is composed of a high proportion of extremely hard primary M7C3 chromium-rich carbides with a typical hardness of 1700 HK*). The carbides are dispersed evenly in a ductile eutectic austenite matrix. Besides a rich chromium content in the wire, additional molybdenum is added to improve overlay toughness, strengthen the matrix, and refine the carbides’ size to increase abrasion resistance and extend service life. The Duroxite® Roller Wire is designed for refurbishing worn rollers with stringer bead welding. The wire is suitable for welding on curved surfaces, and it is feasible to deposit multiple layers up to 75mm (3’’) thick. Preheating, interpass temperature, and post-weld heat treatment are as needed according to the base metal recommendations. It naturally reveals stress-relief cracks after welding.

*) HK is the Knoop microhardness used primarily for very brittle materials.

Key Benefits

- Same wear resistance guaranteed from surface through 75% depth of the overlay.

- Optimal alloy formulation that forms a carbide composition which provides a good combination of wear resistance and homogenous bonding.

- Feasible to weld up to 75mm (3’’) thick to rebuild worn rollers with extreme wear back to their original design.

Typical Applications

Duroxite® Roller Wire is mainly designed to repair roller wear parts which work at temperatures up to 350ºC (660ºF). Typical examples include cement vertical mill rollers and coal pulverizer rollers.

Standard Dimensions

Mechanical Properties

1) Surface hardness is measured on machined flat surface just below overlay surface.

2) ASTM G65 is a standard test measuring sliding abrasion resistance using a dry sand/rubber wheel apparatus. ASTM G65-Procedure A is the most severe test method.

3) ASTM G65 wear test is conducted at 75% depth of the overlay materials to ensure consistently good wear resistance from the top surface through to the depth of 75% of the overlay.

Test results for mechanical properties

Test results for mechanical properties, deposit overlay chemical composition, surface hardness, and ASTM G65-A weight loss were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, substrate chemistry and working temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended applications.

Chemical Composition

(%)

(%)

(%)

(%)

(%)

(%)

Microstructure

The microstructure of Duroxite® Roller Wire is composed of a high proportion of extremely hard primary M7C3 chromium-rich carbides with a typical hardness of 1700 HK dispersed evenly in a ductile eutectic austenite matrix. The volume fraction of primary carbides is maintained between 30 to 50% to provide a good combination of wear resistance and homogenous bonding.

Welding recommendations

Welding parameters recommendations

Recovery: 90%

Delivery Conditions

Fabrication and Other Recommendations

The welded overlay components can be processed by welding, cutting, forming and machining. Specific recommendations can be found in the Duroxite® Product brochure or by consulting your local technical support representative.

Safety precautions

When welding or cutting Duroxite® products, gases and harmful fumes are produced that are chemically complex and difficult to classify. The major toxic component in the fumes is hexavalent chromium. The proper exhaust ventilation equipment and fume-extraction torches are recommended, as well as suitable protective clothing and respiratory protection for operators.