General Product Description

Strenx® Tube 960MH is an HF-welded cold-formed structural hollow section made of hot-rolled high-strength steel with a minimum yield strength of 960 MPa

Its high strength combined with naturally stiff form of welded hollow section enables construction of stronger and lighter structures. Strenx® Tube 960MH meets or exceeds the requirements of EN 10219-3 (2020). Typical applications include load-bearing structures in the lifting, handling and transportation segments.

Strenx® Tube 960MH is available in circular, square and rectangular shapes. Other shapes and sizes are available upon request.

The maximum length of the tubes is 472.440" - 708.660", depending on the size. Longer or cut-to-length tubes are available upon request.

It is not recommended to hot dip galvanize Strenx Tube 960MH hollow sections.

Dimension Range

Other shapes and sizes are available upon request.

Circular Dimensions

Square Dimensions

Rectangular Dimensions

Mechanical Properties

Strenx® Tube 960MH

(min ksi)

(ksi)

(min %)

1) The hollow sections with D/T < 15 (round) or (B + H)/2T < 12,5 (rectangular and square), the minimum value of elongation is reduced by 2.

The mechanical properties for rectangular hollow sections are tested by SSAB on the longer side of the cross section.

Mechanical properties meet the requirements of EN 10219-3 (2020).

Impact Properties

Charpy V 0.393x0.393" test specimen

1) Impact testing according to EN ISO 148-1 is performed on thicknesses ≥ 0.236". The specified minimum value corresponds to a full-size specimen.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

1) Sum of Nb, V and Ti = max 0.22%

Chemical composition meets or exceeds the requirements of EN 10219-3 (2020).

In addition, boron (B), molybdenum (Mo), nickel (Ni) or copper (Cu) may be used as alloying elements either singly or in combination.

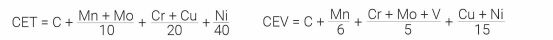

The steel is grain refined.Carbon Equivalent CET(CEV)

Tolerance Circular

Tolerances meet or exceed the requirements of EN 10219

Tolerances meet or exceed the requirements of EN 10219

Tolerances meet or exceed the requirements of EN 10219

Tolerances meet or exceed the requirements of EN 10219

Tolerances meet or exceed the requirements of EN 10219

Tolerances meet or exceed the requirements of EN 10219

Tolerances meet or exceed the requirements of EN 10219

1) All external dimensions are measured with a minimum distance from the end of the section. The distance must be a minimum of 3.937".

Tolerance Square

When 3.937" ≤ B, H ≤ 7.874": ±0.8%

When B, H > 7.874": ±0.6%

1) All external dimensions are measured with a minimum distance from the end of the section. The distance must be a minimum of 3.937".

Tolerance Rectangular

When 3.937" ≤ B, H ≤ 7.874": ±0.8%

When B, H > 7.874": ±0.6%

1) All external dimensions are measured with a minimum distance from the end of the section. The distance must be a minimum of 3.937".

Delivery Conditions

The tubes are cold formed and high frequency welded from thermomechanically rolled steel.