.jpg%3Fm%3D20221215111346&w=3840&q=75)

Hardox® 550

Hardox® 550, with a nominal hardness of 550 HBW, offers a unique combination of excellent abrasion resistance, crack integrity and workshop performance. Hard and tough, it helps to extend the service life of wear parts in heavy-duty and high wear applications.

Hardox® 550 steel with high hardness and toughness

Hardox® 550 is specially designed for heavy wear applications and makes a great alternative to 12% manganese steel castings, 500 Brinell wear plate or bimetals. The additional 50 Brinell you gain in hardness, when upgrading from conventional 500 HBW steels, will increase wear life, though not at the expense of crack integrity. Hardox® 550 is typically used for wear parts in industries like mining, quarrying, mineral processing, earthmoving and recycling.

I’m interested, contact me.jpg%3Fm%3D20221215111559&w=3840&q=75)

.jpg%3Fm%3D20221215111559&w=3840&q=75)

Why Hardox® 550?

- Makes a great alternative to grades with a lower hardness, conventional 500 Brinell steel plate, manganese steel castings or bimetals

- Risks of cracking minimized thanks to its high toughness and excellent surface finish

- Get up to 60% longer service life than with conventional 500 HBW plate, while maintaining crack integrity

- Longer service intervals lead to lower maintenance costs and higher productivity

- Shorter delivery time compared to manganese steel castings

- Get thinner yet higher-performing wear liner packages in truck bodies for lower overall vehicle weight and higher payload

- Workshop benefits: Comes already through-hardened, is machineable and weldable, exceptionally clean steel with guaranteed properties

Typical applications for Hardox® 550

- Wear liners, tailgate liners, liners for apron feeders, crushers, squirt plates, transfer chutes, skip bars, grizzly bars and excavation bucket pads, cutting edges, wear bars, lip shrouds in mining, quarrying and earthmoving.

- Industrial process equipment such as crusher knives, hammers, discs, wedges, shredder rotors, chute liners and hopper liners, ball and SAG mill liners, bolt-on cutting edges, shrouds, vertical and horizontal shaft impactors and gravel washer wear parts.

- Liner plates and other wear parts and components in cement, concrete, steel and energy plants.

- Harvester guide bars in forestry.

.jpg%3Fm%3D20221215111346&w=3840&q=75)

Shredder knives and hammers in recycling

.jpg%3Fm%3D20221215111346&w=3840&q=75)

Shredder knives in 25 mm (0.984”) thick Hardox® 550 were cut with abrasive water jet cutting. When replacing AR500 steel, it typically leads to an increase in service life of 30%.

Jaw crusher cheek plates in quarries and mineral processing

.jpg%3Fm%3D20221215111347&w=3840&q=75)

Cheek plates for the jaw crusher in a granite quarry are made of Hardox® 550. They replaced 12% Mn steel and increased service life by 70%.

Liners for buckets

.jpg%3Fm%3D20221215110334&w=3840&q=75)

A complete liner package of Hardox® 550 for a bucket in a copper mine increased service life by 25%, compared to an AR500 steel.

Screens

.jpg%3Fm%3D20221215111347&w=3840&q=75)

Clinker screens in Hardox® 550 in a cement plant increased service life by 40%, compared to an AR450 steel.

Hardox® WearCalc

The Hardox® WearCalc app is an easy tool to see how much longer service life Hardox® 550 can provide. The chart shows relative wear life with Hardox® WearCalc and magnetite-based iron ore.

Hardox® 550 can give equipment an extra 60% longer service life compared to a 500 HBW AR plate, depending on the application. Not only will the equipment last longer, but the narrow hardness interval of 525-575 HBW gives a consistent wear life, enabling more precise maintenance planning.

Explore a selection of Hardox® 550 applications.jpg%3Fm%3D20221215130724&w=3840&q=75)

Why Hardox® 550 outperforms parts in manganese steel

Hardox® 550 is a genuine alternative to wear parts made of manganese steel. Manganese steel rarely reaches 550 HBW. And if it does, it happens only when exposed to extreme impact wear. For sliding wear, it usually stays at a moderate hardness of 400-450 HBW.

Hardox® 550 always performs at typically 550 HBW — no matter the type of wear — so your wear parts will last longer. Unlike cast manganese wear parts, you can machine and weld Hardox® 550, making it easy to produce custom wear parts in standard machines and workshop setups.

Upgrading to Hardox® 550 is simple

Users of standard 500 HBW AR plate or Hardox® 500 don’t want to give up toughness or workability for an extra 50 HBW. We developed Hardox® 550 with precisely this in mind. Upgrading to Hardox® 550 is a simple and straightforward process. You get the additional hardness, and the steel is still easy to process in the workshop thanks to its high toughness.

You can do the upgrade with practically no changes to your designs or workshop routines. You can weld and machine this steel using the same machinery as for a 500 HBW steel.

Get upgrading support from your local SSAB Technical Development ManagerWhere to get your Hardox® 550

You can purchase Hardox® 550 wear steel when and where you need it, thanks to local availability on a worldwide scale. The most common Hardox® grades and dimensions can be delivered to you directly from an SSAB mill or from nearby SSAB stocks in less than 48 hours. A worldwide source for wear parts in Hardox® 550 and other Hardox® grades is Hardox® Wearparts, our network of more than 550 wear service centers.

Find your local Hardox® supplier.jpg%3Fm%3D20221215111239&w=3840&q=75)

Mechanical Properties

(mmin)

(HBW)

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface for plate. At least one test specimen per heat and 40 tons.

The nominal material thickness will not deviate more than ± 15 mm from that of the test specimen.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Impact Properties

Charpy V 10x10 mm test specimen 1)

1) Impact toughness measured upon agreement. Impact testing according to ISO EN 148 per heat and thickness group. Average of three test.

2) Typical value for 20 mm.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

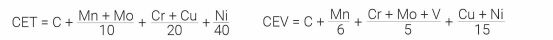

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantees.

Hardox® Guarantees meet the requirements of EN 10029 Class A, but offer more narrow tolerances.

Length and Width

According to SSAB’s dimension program.

Tolerances according to SSAB´s mill edge standards or tolerances that conform to EN 10029.

Shape

Tolerances according to EN 10029.

Flatness

Tolerances according to Hardox® Flatness Guarantees Class D, which are more restrictive than EN 10029 class N.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched. The plates are delivered with sheared or thermally cut edges. Untrimmed edges after agreement.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Hardox® wear plate is not intended for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 250ºC .

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.