Hardox® HiTuf

General Product Description

The extra-high tough steel for structural wear parts

Hardox® HiTuf is an abrasion-resistant plate with guaranteed impact toughness. With a nominal hardness of 350 HBW, it’s a good choice for structural wear parts like thick cutting edges, demolition tools and rippers.

Mechanical Properties

(mmin)

(HBW)

(MPaksi), not guaranteed

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface for plate. At least one test specimen per heat and 40 tons.

The nominal material thickness will not deviate more than ± 15 mm from that of the test specimen.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Impact Properties

Charpy V 10x10 mm test specimen 1)

1) Impact testing according to ISO EN 148 per heat and thickness group. Average of three tests. Single value minimum 70% of specified average.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

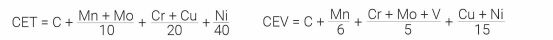

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantees.

Hardox® Guarantees meet the requirements of EN 10029 Class A, but offer more narrow tolerances.

Length and Width

According to SSAB’s dimension program. Tolerances conforms to EN 10029 or to SSAB’s standard after agreement.

Shape

Tolerances according to EN 10029.

Flatness

Tolerances according to Hardox® Flatness Guarantees Class C, which are more restrictive than EN 10029 class N.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched. The plates are delivered with sheared or thermally cut edges. Untrimmed edges after agreement.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Hardox® HiTuf is not intend for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 450ºC .

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.