General Product Description

SSAB’s ASTM/ASME A/SA 516 Hydrogen-Induced Cracking (HIC) tested steels are normalized, carbon steel pressure vessel plates intended for moderate and lower-temperature service where improved notch toughness is important and are additionally produced using special production practices intended to provide improved resistance to hydrogen-induced cracking in wet hydrogen sulfide environments. The HIC testing of these steels is conducted in accordance with NACE TM0284.

Applications

SSAB’s ASTM/ASME A/SA 516 Hydrogen-Induced Cracking (HIC) tested steels are intended for pressure vessel applications for which NACE TM0284 testing has been specified. NACE TM0284 is a test method for evaluating the resistance of pressure vessel steels to hydrogen-induced cracking caused by hydrogen absorption from aqueous sulfide corrosion and is not intended to evaluate resistance to other negative effects of sour service environments.

Dimension Range

(in)

(in)

(in)

Thickness: Inquire for thicknesses less than 0.375 inches and down to 0.250 inches.

Width: Inquire for widths 60 inches up to 72 inches and greater than 120 inches.

Length: Inquire for lengths less than 240 inches and greater than 600 inches and up to a maximum length of 615 inches.

Mechanical Properties

Tensile testing is performed in the transverse direction according to ASTM A20 requirements. The required mechanical properties are tabulated below:

(min ksi)

(ksi)

(min %)

(min %)

(min ksi)

(ksi)

(min %)

(min %)

(min ksi)

(ksi)

(min %)

(min %)

1) Refer to ASTM A20/A20M for Elongation adjustments based on plate thickness.

Chemical Composition

(Heat Analysis, wt. %, maximum unless indicated)

Meets chemical requirements of ASTM/ASME A516-60/SA516-60, A516-65/SA516-65, and A516-70/SA516-70. ASTM/ASME A/SA 20 limits for unspecified elements apply.

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

1) For each reduction of 0.01% below the specified maximum for carbon, an increase of 0.06% above the specified Mn max. is permitted, up to a max. of 1.50%.

2) Grade 60 plates less than or equal to 0.500 inches in thickness may have 0.60-0.90% Mn.

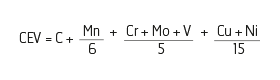

Carbon Equivalent

1) Thickness value is the maximum.

2) Inquire for availability of more restrictive limits.

Tolerances

Tolerances for Mill Plate:

Thickness, width and length tolerances for A516, Grade 60, 65, and 70 plates are in accordance with ASTM/ASME A/SA 20. ASTM/ASME A/SA 20 Half- Standard Flatness tolerances are available for plate thicknesses of 3/8 inches to 2.0 inches. Inquire for specific mill flatness capabilities.

Delivery Conditions

Steel used for ASTM/ASME A/SA 516 HIC tested products is vacuum degassed and the plates are supplied in the normalized condition.

HIC Testing Parameters

HIC requirements are only guaranteed in the normalized plus stress-relieved/post-weld heat-treated (PWHT) condition.

The NACE TM0284 HIC testing is performed using samples in the stress-relieved/post-weld heat treated condition. As such, these test results may not be applicable to components fabricated from this steel unless the whole part receives a similar stress-relieving/post-weld heat treatment.

HIC testing method and NACE solution: TM0284 Solution A.

HIC requirements accepted: Note there are 3 sections/specimen and 3 specimens/sample.

Sample(overall) averages: CLR <= 5%; CTR <= 1.5%; and CSR <= 0.5%.

Inquire for individual maximum specimen or section CLR.

Individual section values, specimen averages and sample average reported for CLR, CTR, and CSR per NACE TM0284-2016 section 10.4.

Minimum stress relief/PWHT required to guarantee HIC tested performance: 1 hour/inch @ 1125°F with a 1 hour minimum.

Maximum PWHT: For A516-70 this product is capable of a customer specified PWHT cycle of 1 hour/inch at 1175°F up to a maximum thickness of 2.0 inches. Inquire for SPWHT temperatures outside the minimum of 1125°F and the maximum of 1175°F for 1 hour/inch with a 1 hour minimum.

HIC test frequency: Thinnest plate per heat, additional testing provided at additional cost.

Weldability

Welding of ASTM/ASME A/SA 516, HIC tested Grades of 60, 65, and 70 shall be performed in accordance with the applicable welding code(s). Special welding consumables and welding procedures may be required to avoid detrimental effects for a given application. Low hydrogen practices are strongly recommended, including the removal of surface moisture. For additional welding information, please contact your SSAB representative.

Supplementary Requirements

By agreement between the purchaser and plate manufacturer, the following Supplementary Agreements may be specified on the purchase order: S1. Vacuum Treatment; S2. Product Analysis; S3. Simulated Post-Weld Heat Treatment of Mechanical Test Coupons; S6. Drop Weight Test; S8. Ultrasonic Examination in accordance with A435; and S12. Ultrasonic Examination in accordance with ASTM A578; S20. Maximum Carbon Equivalent for Weldability.