General Product Description

AR200 steel plate is a carbon-manganese steel product with a nominal hardness of 200 Brinell (HBW). It is intended for moderate wear applications. AR200 is available as mill plate, temper leveled plate or as coils. AR200 is not intended for structural applications.

Applications

Typical applications for AR200 steel plate include cement mixer drums and fins, bulk material handling chute liners, skirtboard liners, and screw conveyers.

Available Dimensions

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

Mill Plate: Please inquire for plate thicknesses less than 0.500 inches down to 0.375 inches, widths less than 72 inches and greater than 103 inches, and for plate lengths less than 120 inches and greater than 1020 inches.

Temper Leveled Plate: SSAB's Cut-To-Length facilities use the temper leveled coil (TLC) process to produce temper leveled plate products. For additional information concerning our temper leveling process, please refer to our SSAB Americas: North American Cut-to-Length Operations brochure located under the Downloads section of our Commercial Steels Overview page.

Coils: Please inquire for coil thicknesses less than 0.188 inches and for coil widths less than 60 inches. Slitting capabilities are determined by strength levels and thicknesses, so please inquire all slit coil opportunities.

Mechanical Properties

AR200 has a nominal hardness of 200 HBW. It is produced to a specified chemical composition only; if an application requires specific mechanical properties it should be inquired. Brinell hardness, if specified, is tested according to ASTM A370, on a surface milled or ground from 0.020” to 0.118” (0.5 - 3.0 mm) below the plate surface. Typical hardness range is 185 to 241 HBW. Inquire for other HBW requirements.

Chemical Composition

Maximum wt % based on ladle analysis.

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

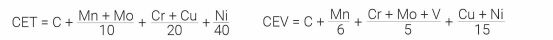

Carbon Equivalent

Tolerances

Tolerances for Mill Plate:

Thickness, width and length tolerances for AR200 plates are in accordance with ASTM A6. ASTM A6 Standard Flatness Tolerances are available for plate thicknesses less than 0.500 inches and A6 Half-Standard Flatness tolerances are available for plate thicknesses of 0.500 inches up to 1.25 inches. Inquire for specific mill flatness capabilities.

Tolerances for Temper Leveled Plate:

Thickness, width and length tolerances for AR200 plates are in accordance with ASTM A6. For thicknesses less than 0.188 inches, flatness tolerances are per ASTM A568 Table 13.1. The flatness tolerances for thicknesses 0.188 inches and greater are per ASTM A6 Half-Standard Flatness Tolerances or better are available for temper leveled plates. Flatness capabilities are determined by the processing line and the minimum yield strength of the material.

Tolerances for Coils for Conversion To:

For minimum gauge orders, thickness and width tolerances are in accordance with the respective ASTM specifications of A568 for thicknesses of less than 0.230 inches(exclusive), and A635 for thicknesses of 0.230 inches to 1.00 inch, inclusive. Thickness tolerances are in accordance with Table S1.1 found in each of the ASTM specifications of A635 and A568, respective of thickness. Width tolerances are in accordance with Table 6 of ASTM A568 and Table 3 of ASTM A635. Thickness tolerances for nominal gauge orders must be inquired.

Cutting

AR200 steel plate can be thermally cut satisfactorily. The hardened, heat-affected zones adjacent to the cut surfaces should be removed before any subsequent forming or welding operation.

Formability properties

AR200 may be employed in moderate cold forming applications. Proper edge preparation (i.e. removal of hardened heat-affected zones adjacent to the cut surfaces) is essential to minimize the potential for cracking. Cold forming should be performed at a minimum temperature of 68°F (20°C). Minimum recommended punch radius, R, and die width opening, W, as a function of bending orientation is provided in the following table.

1) Inquire for thicknesses of 0.315 inches down to 0.100 inches.

Weldability

AR200 is weldable by conventional electric arc welding processes when using low-hydrogen consumables and appropriate welding practices. The following recommendations should be considered.

When matching consumables are not required, lower strength electrodes are recommended. Slow-cooling after welding and a post-weld heat treatment at 1100°F (595°C) are suggested to minimize cold cracking. The electrodes for shielded metal arc welding must be properly stored and dried; welding flux must be dried and free from moisture for submerged arc welding.

1) Inquire for thicknesses less than 0.315 inches down to 0.100 inches.