Hardox® pipes and tubes

Abrasion-resistant steel pipes and tubes give you extreme performance and extended service life almost anywhere you have heavy wear. Despite their hardness, Hardox® pipes and tubes can be welded, cut, milled and drilled using standard workshop practices.

Hardox® abrasion-resistant pipes and tubes for high wear performance and long service life

As hard and tough as our wear plate, Hardox® pipes and tubes offer outstanding performance when you need both high abrasion resistance and a lighter product. These long-lasting, abrasion-resistant steel pipes and wear-resistant steel tubes at a hardness of 400 HBW or 500 HBW can replace costly wear products like hard-faced overlay pipe and high-chrome white iron.

High-strength steel pipes extend service life in tough environments

Want to extend your equipment’s service life 2, 5 or 10 times or more? Do you need abrasion-resistant steel pipes for tough materials like wet concrete, slurry, soil, gravel, sand or wet coal ash? Is your equipment used in challenging sectors like mining, cement, dredging, recycling or steel production? Or perhaps you need a tubular part that can serve as a structural component in a bucket or other piece of equipment. If so, Hardox® 400 Tube or Hardox® 500 Tube can be the right steel tube to get the job done.

Interested in what Hardox® Pipes and Tubes can do for your equipment?

Benefits of Hardox® steel pipes and tubes

- Can outlast mild steel pipe and tube by an average of 5 times

- Extended service life reduces maintenance costs and unplanned stops

- Lighter-weight constructions deliver high strength

- Range of diameters available

- Standard or custom pipe sizes

- Easy installation and field repair

- Great alternative to heavy, not weldable cast wear pipe

- Strong and tough enough for structural applications

Typical abrasion resistant tubing and piping applications include

- Concrete pump pipe in concrete mixers

- Slurry pipes

- Other industrial pipe (for ash, soil or gravel)

- Dredging pipe and dredging equipment

- Hard, fixed dust collection pipe

- Agriculture, for transporting and handling corn, cereal and other products

- Structural applications in buckets and other heavy equipment attachments

- Applications that require greater strength, closer tolerances and a superior finish

Steel pipes and extreme wear challenges

When abrasive slurry is conveyed through steel pipe, its impact on the pipe’s inner surface can be devastating. It can cause severe problems for equipment in service, especially for pipe systems used to transport slurries that contain tailings or ores from mining operations. Such abrasive and erosive wear can cause some serious financial damage, too – loss of production time and expensive repairs.

Find out what Hardox® Pipes and Tubes can do for your equipment

Why high-strength abrasion-resistant steel beats mild steel pipe in abrasive environments

In transportation systems that use pipes, abrasive wear occurs when hard particles or abrasive slurry particles slide along the wall of the pipe or are forced against it. This action on the pipe wall can cause loss of material and, in extreme cases, pipe leaks or failure.

Mild steel pipe simply cannot stand tough enough against such abrasive environments to give acceptable service life. While mild steel pipe has good strength and impact resistance, it has poor abrasion resistance compared with high-strength, abrasion-resistant steel pipe in such high-wear areas.

What about cast wear pipe? In conveying applications, the pipes are constantly being subjected to movement due to pressure surges. Heavy, brittle cast piping is not a good option in such piping systems.

Abrasion-resistant steel pipe like Hardox® pipes in high-strength steel give you a maintenance-friendly alternative in abrasive or tough applications. And you can use lighter pipes with thinner wall thickness. They are easier to handle and install and will maintain the strength you need.

Get your own pipes and tubes consultation now

Hardox® tubes save weight and last longer in Remu’s screening buckets

Hardox® steel tubes are vital components inside the Finnish company Remu’s screening buckets. The screening is performed by rotors with blades in Hardox® 500 wear plate that are welded to a Hardox® 500 Tube. The rotors separate bigger particles or grind aggregated material into smaller particles, causing a lot of wear on the blades and the tubes.

By upgrading from hardfaced tubes in S355 steel to Hardox® 500 Tube, Remu reduced the thickness of the tubes to save weight and get extended service life as an extra bonus.

How Hardox® Tubes work hard for RemuPipes and tubes – what’s the difference?

There is no technical difference between Hardox® tubes and pipes. They have the same mechanical and chemical properties and wear performance. Typically, we call them tubes when they are used in structural applications subjected to outside wear, and pipes when they are used for pumping abrasive liquids or slurries. In either case, it’s a good thing Hardox® steel is through-hardened – this means it has high wear resistance throughout, from the core outwards to the surface.

Strength of Hardox® steel tubes confirmed with pressure testing

Hardox® round steel tubes have undergone extensive pressure testing. During testing of Hardox® 400 tubes, all dimensions could withstand a peak pressure of 60 MPa (8.70 ksi) for at least six hours. In a test of Hardox® 500 tubes, a peak pressure of 85 MPa (12.33 ksi) was achieved.

Uniform, guaranteed properties for excellent workshop performance

Hardox® abrasion-resistant pipes and tubes are roll formed and plasma welded prior to quenching. This guarantees that the mechanical properties in the weld are the same as in the rest of the material, resulting in a more durable steel tube or pipe.

With their lean proprietary chemistries and outstanding cleanliness, these abrasion-resistant steel pipes and tubes have highly consistent properties. This gives you precision and efficiency in the workshop. Despite their hardness, Hardox® tubes can be welded, cut, milled and drilled using standard workshop practices.

Hardox® 400 Tube and Hardox® 500 Tubes comply with standard EN 10210 in terms of dimension tolerances and testing.

Download workshop guidelines for Hardox® pipes and tubes

Dimension Range

Hardox® Tubes are available in circular shape.

Other lengths are available upon request.

Circular Dimensions

Mechanical Properties

(inmm)

(HBW)

(inmm)

(HBW)

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

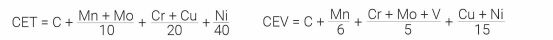

Carbon Equivalent CET(CEV)

Tolerances

1) All external dimensions are measured with a minimum distance from the end of the section. The distance must be a minimum of 3.937 inches.

Delivery Conditions

Hardox® Tubes and pipes are delivered in quenched condition except for diameters above 5.236", which are delivered in as-rolled condition.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Hardox® 500 Tube and pipes has obtained its mechanical properties by quenching and after roll forming and plasma welding. The properties of the delivery condition cannot be retained after exposure to service or preheating temperatures in excess of 482ºF. Hardox® 500 Tube and pipes is not intended for further heat treatment.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.