Hardox® 500

General Product Description

The bendable, weldable and highly abrasion-resistant steel. Hardox® 500 is a bendable and weldable abrasion-resistant steel with a nominal hardness of 500 HBW. Suitable for applications that demand higher wear resistance. Hardox® 500 increases payload and service life while maintaining good processability and toughness.

Dimension Range

Hardox® 500 is available as plate in thicknesses of 0.157 - 4.055”, and as sheet in thicknesses of 0.079 - 0.275”. Hardox® 500 plate is available in widths up to 131.89” and lengths up to 575.98”. Hardox® 500 sheet is available in widths up to 64.96” and lengths up to 62.92”. More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

(inmm)

(HBW)

(ksiMPa), not guaranteed

(inmm)

(HBW)

(ksiMPa), not guaranteed

(inmm)

(HBW)

(ksiMPa), not guaranteed

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.019 – 0.118" below surface. At least one test specimen per heat and 40 tonnes. The nominal thickness of supplied plates will not deviate more than +/- 0.590" from the thickness of the test specimen used for hardness testing. For sheet the Brinell hardness test is according to EN ISO 6506-1 on each heat treatment individual/coil. Hardness is measured on a milled surface 0.012 - 0.079" below surface.

2) Hardness test is not performed or guaranteed for Hardox® products with thicknesses < 0.098". The tabulated hardness values for thickness < 0.098" is a conversion from the tensile strength.

For more information please see the datasheet 2067- Hardness conversion of thin Hardox® wear sheet.

Hardox® wear plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum hardness.

Impact Properties

Charpy V 0.393 x 0.393" test specimen 1)

1) Impact toughness measured upon agreement. For thicknesses between 0.118" and 0.469", subsize Charpy V-specimens are used. The specified impact toughness is then proportional to the cross-sectional area of the test specimen, compared to a full-size specimen (0.393" x 0.393"). Impact testing according to ISO EN 148. Average of three tests.

2) Typical value for 0.787".

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

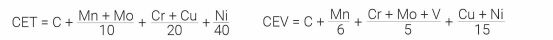

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Hardox® Thickness Guarantee.

Hardox® Guarantees meet the requirements of EN 10029 Class A for plate, but offer more narrow tolerances. For sheets the guarantees meets the requirements of 1/2 EN 10051.

Length and Width

According to SSAB’s dimension program. For plate, the tolerances are according to SSAB´s mill edge standard or tolerances that conform to EN 10029. Tolerances conform to EN 10051 for sheet, tighter tolerances available on request.

Shape

Tolerances according to EN 10029 for plate and according to EN 10051 for sheet.

Flatness

Tolerances according to Hardox® Flatness Guarantees Class C for plate, which are more restrictive than EN 10029. For sheet, the tolerances are according to Hardox® Flatness Guarantees Class A, that offer narrower tolerances compared to EN 10051.

Surface Properties

According to EN 10163-2 Class A, Subclass 1.

Delivery Conditions

The delivery condition is Quenched or Quenched and Tempered. Plates are delivered with sheared or thermally cut edges and thicknesses over 3.150" are delivered with mill edge as standard. Sheets are delivered with an as-rolled surface and mill edge as standard.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations can be found in SSABs brochures at www.hardox.com or consult Tech Support.

Bendability for plate is according to Hardox® Bending Guarantees Class F. For sheet, the bendability is according to Hardox® Bending Guarantees Class C.

Hardox® wear plate is not intended for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 482ºF .

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.