General Product Description

Strenx® Section 900MC is a cold-formed steel section made of hot-rolled, high-strength steel with a minimum yield strength of 900 MPa.

Its high-strength combined with naturally stiff form enables construction of stronger and lighter structures. Typical applications include demanding load-bearing structures in the lifting, handling and transportation segments.

The steel in Strenx® Section 700MC meets or exceeds the requirements of EN 10149-2. Its tolerances meet or exceed, when applicable, the requirements of EN 10162.

Strenx® Section 900MC is available as U-section. Other shapes and variations are available upon request. The maximum length of the sections is 826.770", cut-to-length sections are available upon request.

Dimension Range

Strenx® Section 900MC is available as U-section. Other shapes and variations are available upon request.

Mechanical Properties

(inmm)

(inmm)

(min ksiMPa)

(ksiMPa)

(min %)

(x t)

The mechanical properties are tested in the longitudinal direction.

1) If ReH is not applicable then Rp0.2 is used. On thicknesses >0.315" the minimum yield strength may be 2.9 ksi lower.

Impact Properties

1) Impact testing according to EN ISO 148-1 is performed on thicknesses ≥ 0.236". The specified minimum value corresponds to a full-size specimen.

Chemical Composition (heat analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

If the material is to be hot-dip galvanized according to category A or category B in EN 10149-2 this must be specified at the time of order.

Sum of Nb, V and Ti = max 0.22%

The steel is grain refined.

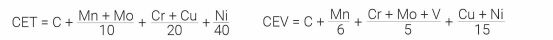

Carbon Equivalent CET(CEV)

Tolerances

Delivery Conditions

The sections are roll formed from thermomechanically rolled steel.

Fabrication and Other Recommendations

Welding, bending and machining

Strenx® Section has good weldabilility, including corner region, and it is suitable for thermal cutting. All the common welding methods are suitable with matching or undermatching consumables.

Sections can also be sawed and machined with regular tools. Bending of the sections is also possible, please contact Tech Support for further instructions. For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the product.

Show specs in: