General Product Description

API 2H Grade 50 is an intermediate-strength, normalized, structural steel plate used in the welded construction of offshore structures. API 2H Grade 50 has a minimum yield strength of 50 ksi [345 MPa] and a minimum transverse Charpy V-notch impact toughness of 30 ft-lb [41 J] at -40°F [-40°C]. SSAB is an API Licensee under the API Monogram Program. This product can be multicertified to ASTM A633 Grade C, ABS DH/EH 36, ASTM A537 Class 1 and MIL-S-22698 DH36 Rev C in thicknesses to 2” [50.8 mm].

Applications

API 2H Grade 50 is intended primarily for use in offshore structures in critical portions that must exhibit good impact toughness and resistance to plastic fatigue loading and lamellar tearing. The primary use of API 2H Grade 50 is in tubular joints, stiffened plate construction and other intersections where portions of the plates will be subjected to tension in the through-thickness (Z) direction.

Dimension Range

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

Thickness: Inquire thicknesses <0.375” down to 0.250”, inquire widths <72” down to 60”, inquire lengths slightly >600”.

Width: Inquire widths >98” up to 123” where thicknesses are >2.00”.

Mechanical Properties

Tensile testing is performed in the transverse direction according to API 2H requirements. The mechanical property requirements are tabulated below:

(inmm)

(inmm)

(min %)

(min %)

(inmm)

(inmm)

(min %)

(min %)

Impact Properties

Charpy V-Notch Impact Testing is performed using transverse specimens in accordance with ASTM A370. The producer has the option of testing sub-size specimens to any of the combinations of specimen size, energy requirement, and test temperature as shown below:

Chemical Composition

(wt. %, maximum, unless indicated)

(max wt %)

(max wt %)

(wt %)

(max wt %)

(max wt %)

(wt %)

(wt %)

(wt %)

(wt %)

(max %)

1) Minimum value, if any, shall be as agreed upon and stated on the order.

2) Shall not be intentionally added.

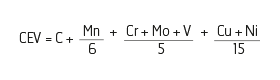

Carbon Equivalent

Tolerances

Thickness, width, and length tolerances for API 2H Grade 50 steel plate are in accordance with the requirements of ASTM A6. The flatness tolerance for as-supplied product is ½ ASTM A6. Orders of thicknesses <0.375” (0.250”-0.374”) will only be supplied to full standard ASTM A6 flatness tolerance.

Delivery Conditions

API 2H Grade 50 is supplied in the normalized condition.

Weldability

Welding of API 2H Grade 50 shall be performed in accordance with the applicable welding code. In the absence of a specified welding code, the following suggested minimum preheat and interpass temperatures and welding consumables are provided. Special welding consumables and welding procedures may be required to match the base metal toughness. Low hydrogen practices are strongly recommended, including the removal of surface moisture.

Supplementary Requirements

By agreement between the purchaser and plate manufacturer, the following Supplementary Requirements may be specified on the purchase order: S1 (Ultrasonic Examination), S2 (Notch Toughness Test at Lower Temperature), S3 (Individual Plate Testing), S4 (Through-Thickness [Z-Direction] Testing), S5 (Low Sulfur Steel for Improved Through-Thickness Properties), S7 (Low Nitrogen Content for Improved Notch Toughness in Strain-Hardened Condition), S8 (Strain-Aged Charpy V—Notch Impact Tests), S12 (Notch Toughness Using Drop Weight) up to 2.00” maximum thickness, S13 (Surface Quality) and S14 (Thickness Tolerance).

Show specs in: