General Product Description

API Specification 5L is the American Petroleum Institute’s specification for seamless and welded line pipe for use in petroleum transportation systems in the petroleum and natural gas industries. SSAB produces plate and coil skelp (the input material to a pipe manufacturing operation) for conversion by a pipe mill into welded line pipe. The specific type of pipe manufacturing operation may alter the mechanical properties of the skelp and consequently orders for skelp by pipe mills are typically each unique relative to the specified skelp quality level, delivery condition, chemical composition limits, and the specified as-delievered skelp properties based on the pipe manufacturing operation and the intented application for the line pipe. As a result, all inquiries for skelp orders are subjected to review. In the pipe body, API 5L Grade X42 pipe has a specified minimum yield strength of 42.1 ksi.

Available Dimensions

All orders are subject to review for applicability for specific pipe manufacturing method. Inquire for other thickness, width, or plate length availability.

(in)

(in)

(in)

(in)

(in)

(in)

Mechanical Properties

(min %)

(min %)

(min %)

(min %)

1) Inquire for mechanical properties requirements for coil and plate skelp.

Chemical Composition

Composition meets PSL2 (X42M) requirements. Inquire for SSC/HIC performance.

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

1) For each reduction of 0.01% below the specified maximum for C, an increase of 0.05% above the specified maximum for Mn is permitted up to a maximum of 1.65% .

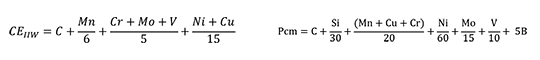

Carbon Equivalent

Composition meets PSL2 (X42M) requirements.

Show specs in: