General Product Description

ABS AQ/DQ/EQ63 are American Bureau of Shipping grades of high-strength, quenched and tempered steel plates for structural applications requiring high yield strength combined with good formability and toughness. ABS AQ/DQ/EQ63 grades have minimum yield strengths of 90 ksi [620 MPa, 63 kgf/mm2] and the different alphabetic indicators AQ, DQ, and EQ identifythe respective Charpy V-notch impact test temperature.

ApplicationsTypical applications for ABS AQ/DQ/EQ63 grades include shipbuilding and mobile offshore drilling units and structures.

Available Dimensions

(inmm)

(inmm)

(inmm)

Thickness: Inquire for thicknesses less than 1 inch and for thicknesses greater than 1.5 inches up to 5.1 inches.

Width: Inquire for widths less than 72 inches and for widths greater than 120 inches up to 131.9 inches.

Length: Inquire for lengths greater than 588 inches up to 600 inches.

Mechanical Properties

Tensile testing is performed in the transverse direction. The required tensile properties are tabulated below:

(min ksiMPa)

(min ksiMPa)

(ksi)

(min %)

(min %)

(min ksiMPa)

(min ksiMPa)

(ksi)

(min %)

(min %)

1) Minimum Average Reduction in Area when Z25 or Z35 Quality Specified.

2) Minimum Individual Value Reduction of Area when Z25 or Z35 Quality Specified.

Through-Thickness Tension Testing, “Z” Quality

When “Z” quality steel is specified, through-thickness tension testing is performed in accordance with ABS Rules and ASTM A770. Two “Z” quality steels are available, Z25 and Z35. The through-thickness tension testing reduction of area requirements for each are tabulated in the table.

Impact Properties

Charpy V-notch impact testing is performed with longitudinal test specimens. Please inquire if transverse Charpy V- notch specimen testing is required.

1) Charpy V-notch impact testing of AQ63 is not required unless explicitly ordered.

2) Minimum average energy for full-size specimens. Refer to ABS Rules for sub-size specimen energy requirements.

Chemical Composition

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

1) 0.008% maximum S for Z-Quality plates.

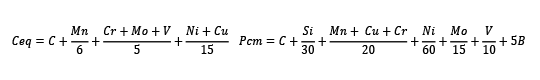

Carbon Equivalent

Ceq and Pcm typical values are based on historical averages.

Tolerances

Thickness tolerances for ABS AQ/DQ/EQ63 steel plates are in accordance with the requirements of ABS Rules 2-1-1/15.

Length and width tolerances for ABS AQ/DQ/EQ63 steel plates are in accordance with ASTM A6.

Show specs in: