General Product Description

ABS Grades AH32, DH32, and EH32 Z25 are "Z" quality, higher-strength structural steels with a minimum specified yield strength of 46 ksi and specified minimum Charpy V-notch impact toughness properties. The Z25 quality steel has a minimum specified average value for reduction of area in through- thickness tensile testing of 25%.

ApplicationsTypical applications include shipbuilding and mobile offshore drilling units and structural details for which greater resistance to lamellar tearing is desired.

Available Dimensions

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

Mechanical Properties

Tensile testing is performed in the transverse direction. When "Z" quality steel is specified, through-thickness tension testing is performed in accordance with ABS Rules.

(inmm)

(min ksi)

(ksi)

(min %)

(min %)

(min %)

(inmm)

(min ksi)

(ksi)

(min %)

(min %)

(min %)

(inmm)

(min ksi)

(ksi)

(min %)

(min %)

(min %)

1) See ABS Rules for elongation requirements for alternative tensile specimens.

Impact Properties

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

1) Specimen orientation at the option of the manufacturer unless otherwise specified in the order.

No more than one value below the specified miniminum average energy but no less than 70% of the specfied minimum average energy value.

Minimum average energy for full-size specimens. Refer to ABS Rules for sub-size specimen energy requirements.

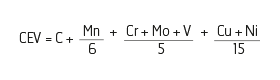

Carbon Equivalent

1) Carbon equivalent requirements for TMCP condition of supply only.

Show specs in: