General Product Description

The ASTM A516 specification is the Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower Temperature Service for plates with the intended service in welded pressure vessels where improved notch toughness is important. SSAB's A516-65 and ASME SA516-65 steel plate products are made from carbon-manganese steels and produced to pressure vessel quality(PVQ) standards as delineated in ASTM A20/ASME SA20.

Applications

Typical applications are pressure vessels designed for moderate and lower-temperature service requiring excellent notch toughness as well as API 650 and API 620 storage tanks.

Dimension Range

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

Mill plate: As-rolled mill plates are available in the thickness range of 0.188 inches to 1.50 inches. Normalized mill plates are available in thicknesses of 0.236 inches to 3.54 inches.

Mill plate dimensions: Inquire for plate thicknesses of 0.250 inches up to 0.375 inches for normalized plates. Inquire for widths 60 inches up to 72 inches and greater than 120 inches. Inquire for lengths less than 240 inches and slightly over 600 inches for normalized plates.

Temper leveled plate: SSAB's Cut-To-Length facilities use the temper leveled coil (TLC) process to produce temper leveled plate products. For additional information concerning our temper leveling process, please refer to our SSAB Americas: North American Cut-to-Length Operations brochure located under the Downloads section of our Commercial Steels Overview page.

Coil for convertion to product: Coils are excluded from qualification to this specification until they are processed into a finished plate product and all required processing, inspections, and testing are performed. Coils For Conversion To product will be certified to chemistry only. Coils will be subject to availability, so please inquire.

Coil for convertion to product width: Inquire for coil widths less than 72 inches.

Mechanical Properties

Tensile testing is performed in the transverse direction according to ASTM A20 requirements. The required mechanical properties are tabulated below:

(min ksi)

(ksi)

(min %)

(min %)

1) Refer to ASTM A20/A20M for Elongation adjustments based on plate thickness.

Chemical Composition

(Heat Analysis, wt. %, maximum unless indicated)

Meets chemical requirements of ASTM A516-65/SA516-65, as shown below. ASTM A20 limits apply to unspecified elements.

(%)

(%)

(%)

(%)

(%)

(%)

1) For each reduction of 0.01% below the specified maximum for carbon, an increase of 0.06% above the specified Mn max. is permitted, up to a max. of 1.50%.

2) P and S are more restrictive than A516/SA516 requirements. Even lower limits for P and S are available on an inquiry basis.

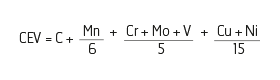

Carbon Equivalent

1) Carbon equivalents (CEV) maximums of 0.43 (up to 1.25 inches maximum thickness) and 0.45 (up to 1.5 inches maximum thickness) are available.

Inquire for more restrictive carbon equivalents specified by ASTM A20 Supplemental Requirement S20.

Tolerances

Tolerances for Mill Plate:

Thickness, width and length tolerances for A516, Grade 65 plates are in accordance with ASTM A20. ASTM A20 Half-Standard Flatness tolerances are available for plate thicknesses of 3/8 inches to 2.0 inches. Inquire for specific mill flatness capabilities. For thicknesses over 2 inches, the flatness guarantee is a maximum of 6mm/m.

Tolerances for Temper Leveled Plate:

Thickness, width and length tolerances for A516, Grade 65 plates are in accordance with ASTM A20. ASTM A20 Half-Standard Flatness tolerances or better are available for temper leveled plates. Flatness capabilities are determined by the processing line and the minimum yield strength of the material.

Tolerances for Coils for Conversion To:

For minimum gauge orders, thickness and width tolerances are in accordance with the respective ASTM specifications of A568 for thicknesses of less than 0.230 inches(exclusive), and A635 for thicknesses of 0.230 inches to 1.00 inch, inclusive. Thickness tolerances are in accordance with Table S1.1 found in each of the ASTM specifications of A635 and A568, respective of thickness. Width tolerances are in accordance with Table 6 of ASTM A568 and Table 3 of ASTM A635. Thickness tolerances for nominal gauge orders must be inquired.

Delivery Conditions

ASTM A516-65/SA516-65 plates greater than 1.50 inches thick are supplied in the normalized condition, unless otherwise ordered. Plates less than or equal to 1.50 inches are generally supplied in the as-rolled condition unless ordered as normalized.

Weldability

Welding of A516-65/SA516-65 shall be performed in accordance with the applicable welding code(s). Special welding consumables and welding procedures may be required to avoid detrimental effects for a given application. Low hydrogen practices are strongly recommended, including the removal of surface moisture. For additional welding information, please contact your SSAB representative.

Supplementary Requirements

By agreement between the purchaser and plate manufacturer, the following Supplementary Agreements may be specified on the purchase order: S1. Vacuum Treatment; S2. Product Analysis; S3. Simulated Post-Weld Heat Treatment of Mechanical Test Coupons; S6. Drop Weight Test; S8. Ultrasonic Examination in accordance with A435; and S12. Ultrasonic Examination in accordance with ASTM A578; S20. Maximum Carbon Equivalent for Weldability.

Show specs in: