General Product Description

AAR TC128 is a high-strength, carbon manganese steel plate for use in fusion-welded tank car tanks with a specified minimum yield strength of 50 ksi. The steel is produced to a fine grain practice and is available to a maximum thickness of 1 in. AAR TC128 is furnished in the as-rolled or normalized condition. When designated for low temperature service, the steel is provided in the normalized condtion with specified low temperature Charpy-V notch impact properties.

Dimension Range

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

Thickness: Inquire for thickness less than 0.375 in.

Width: Inquire for widths greater than 120 in.

Mechanical Properties

Tensile testing is performed in the transverse direction in accordance with ASTM A20. Specimens for tensile testing are prepared from material in the condition specified for plate use such as as-rolled, normalized, or post weld heat treated. The required tensile property requirements are tablulated below:

(inmm)

(min ksi)

(ksi)

(min %)

(min %)

1) See AAR Specifications for Tank Cars for elongation adjustments.

Impact Properties

1) For normalized plates, inquire for impact energy requirements in as-rolled condition.

2) Inquire for requirements at other temperatures.

Chemical Composition

(max wt %)

(wt %)

(max wt %)

(max wt %)

(wt %)

(wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

1) A minimum of 0.015% must be acid-soluble.

2) Silicon range is 0.15 - 0.50 for thickness 0.751 - 1.000.

Tin (Sn) maximum of 0.020, Cu maximum of 0.35.

Cu + Ni + Cr + Mo max 0.65

Nb + V + Ti max 0.11.

Ti/N ratio max 4:1.

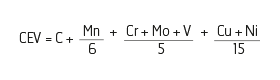

Carbon Equivalent

Show specs in: