General Product Description

AAR ASTM A516 Grade 70 is a produced in accordance with the supplementary requirements of the AAR Specifications for Tank Cars for use in tank car heads, shells, and sumps.

Dimension Range

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

(inmm)

1) Inquire for availability.

Mechanical Properties

Tensile testing is performed in the transverse direction in accordance with ASTM A20. Specimens for tensile testing are prepared from material in the condition specified for plate use such as as-rolled, normalized, or post weld heat treated. The required tensile property requirements are tablulated below:

(inmm)

(min %)

(min %)

Impact Properties

1) Inquire for requirements at other temperatures.

2) For normalized plates, inquire for impact energy requirements in as-rolled condition.

Chemical Composition

(max wt %)

(wt %)

(max wt %)

(max wt %)

(wt %)

(wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

(max wt %)

1) For each reduction of 0.01% below the specified maximum for carbon, an increase of 0.06% above the specified Mn max. is permitted, up to a max. of 1.50%.

2) A minimum of 0.015% must be acid-soluble.

Tin (Sn) maximum of 0.020.

Cu + Ni + Cr + Mo max 0.65.

Nb + V + Ti max 0.11.

Ti/N ratio max 4:1.

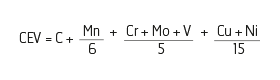

Carbon Equivalent

Show specs in: