Get your Hardox® round bars here

To satisfy our customers’ growing demand for Hardox® round bars, we have improved local availability in order to speed up deliveries. The most common dimensions of Hardox® round bars are stocked at 15 sales locations worldwide, making it easy to order production material and test samples. The local stocks can also be customized to provide certain dimensions. The central stock for Hardox® round bars is located in Antwerp, Belgium. The production stock is located in Sweden.

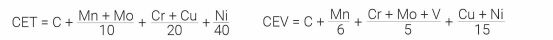

The map shows central and local stocks. For available dimensions and delivery conditions in your area, contact SSAB sales.