Mechanical Properties

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(min %)

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(min %)

The mechanical properties are tested and guaranteed in both longitudinal and transverse direction.

1) If ReH is not applicable then Rp0.2 is used.

Impact Properties

Charpy V 10x10 mm test specimen

Charpy V 10x10 mm test specimen

1) Impact testing according to EN ISO 148-1 is performed on thicknesses ≥ 6mm. For thicknesses between 6.0 - 8.0 mm, sub-size Charpy V-specimens are used. The specified min value is then proportional to the cross-sectional area of the specimen compared to a full-size specimen (10x10 mm).

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined.

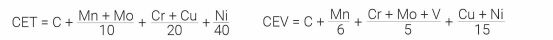

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Strenx® Thickness Guarantees.

Strenx® Guarantees offer considerably narrower thickness tolerances compared to EN 10051.

Length and Width

Width and length tolerances according to SSAB standard.

The SSAB standard offer narrower width and length tolerances compared to EN 10051.

Length tolerances only apply for cut to length sheets.

Shape

Tolerances according to EN 10051. Narrower tolerances according to the SSAB standard are available on request.

Flatness

Tolerances according to Strenx® Flatness Guarantees Class A.

Strenx® Flatness Guarantees offer narrower tolerances compared to EN 10051.

Flatness guarantees only apply for cut to length sheets.

Surface Properties

According to EN 10163-2 Class A, Subclass 3.

Delivery Conditions

The delivery condition is Q+T (Quenched and Tempered). Strenx® Plus is supplied in as rolled surface condition, pickled surface is available in a limited thickness range.

Delivery requirements can be found in SSAB’s brochure Strenx® Guarantees or on www.ssab.com.

Fabrication and Other Recommendations

Welding, bending and machining

Strenx® Plus has very good weldability with good toughness and strength in the welds. Strenx® Plus has good forming and cutting performance.

Strenx® Plus is not suited for applications requiring hot working or heat treatments at temperatures above 400°C, since the material then may lose its guaranteed properties.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the products.

Strenx® 960 Plus high-strength structural steel

Show specs in: