General Product Description

Strenx® 960 E/F is a structural steel with a minimum yield strength of 850-960 MPa depending on thickness.

Strenx® 960 E fulfills the requirements for S960QL in EN 10025-6 and Strenx® 960 F for S960QL1. Typical applications include demanding load-bearing structures.

Strenx® 960 E/F benefits include:

- Exceptional consistency within a plate guaranteed by close tolerances

- High impact toughness which provides for good resistance to fractures

- Superior bendability and surface quality

- Weldability with excellent HAZ strength and toughness

Mechanical Properties

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

(mmin)

(mmin)

(min MPaksi)

(MPaksi)

(min %)

For transverse test pieces.

Impact Properties

Charpy V 10x10 mm test specimen 1)

Charpy V 10x10 mm test specimen 1)

1) Unless otherwise agreed, transverse impact testing according to EN 10025-6 option 30 will apply. For thicknesses between 6 - 11.9 mm, sub-size Charpy V-specimens are used. The specified minimum value is then proportrional to the cross-sectional area of the specimen compared to a full-size specimen (10 x 10 mm).

Chemical Composition (ladle analysis)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

The steel is grain refined. *) Intentional alloying elements.

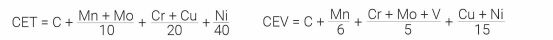

Carbon Equivalent CET(CEV)

Thickness

Tolerances according to Strenx® Thickness Guarantees.

Strenx® Guarantees meet the requirements of EN 10029 Class A, but offers narrower tolerances.

Length and Width

According to SSAB’s dimension program. Tolerances conform with EN 10029 or to SSAB’s standard after agreement.

Shape

Tolerances according to EN 10029.

Flatness

Tolerances according to Strenx® Flatness Guarantee Class C, which are more narrow than EN 10029 Class N.

Surface Properties

According to EN 10163-2 Class A, Subclass 3.

Delivery Conditions

The delivery condition is Quenched and Tempered. The plates are delivered with sheared or thermally cut edges. Untrimmed edges after agreement.

Delivery requirements can be found in SSAB’s brochure Strenx® Guarantees or on www.ssab.com.

Fabrication and Other Recommendations

Welding, bending and machining

Recommendations are found in SSAB’s brochures at www.ssab.com or consult Tech Support.

Bendability according to Strenx® Bending Guarantee Class B.

Strenx® 960 E/F has obtained its mechanical properties by quenching and subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 550ºC.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on this product. Grinding, especially of primer coated plates, may produce dust with a high particle concentration.

Show specs in:

Ready to upgrade?

Take the opportunity to improve the performance and reduce the weight of your equipment by upgrading from Strenx® 960 E/F to Strenx® 1100 E/F. The increase in yield strength by 15% allows for an equal increase in the equipment’s load-bearing capacity. Get in touch with our steel specialists at SSAB Tech Support or SSAB Knowledge Service Center for an update on upgrading.