General Product Description

API 2MT1 is an intermediate-strength structural steel plate used in the welded construction of offshore structures. API 2MT1 has a minimum yield strength of 50 ksi [345 MPa] and a minimum transverse Charpy V-notch impact toughness of 30 ft-lbf [41 J] at 0°F [-18°C]. SSAB is an API Licensee under the API Monogram Program.

Applications

API 2MT1 is intended primarilyfor use in offshore structures for Class “B” applications as defined in API RP 2A. API 2MT1 steel plates are suitable for use in select portions of offshore structures which must resist impact and plastic fatigue loading but are not subjected to substantial through-thickness (Z- direction) stresses.

Dimension Range

(in)

(in)

(in)

(in)

Dimensions: Inquire thickness <0.375", inquire widths <72" down to 60".

Length: Rail shipments the maximum length of 1080" applies; for truck shipments the maximum length of 1020" (25,908mm) applies.

Mechanical Properties

Tensile testing is performed in the transverse direction according to ASTM A6 and A370 requirements. The minimum values are tabulated below:

(in)

(in)

(min %)

(min %)

Impact Properties

Charpy V-Notch Impact Testing is performed in accordance with ASTM A370 and ASTM A673 Frequency (H).

Chemical Composition

(wt. %, maximum, unless indicated)

(max wt %)

(max wt %)

(wt %)

(max wt %)

(max wt %)

(wt %)

(%)

(wt %)

(wt %)

(max wt %)

(max wt %)

(max %)

(max wt %)

1) Analyzed for either total aluminum or soluble aluminum. The soluble aluminum range is 0.015 to 0.055%.

2) Minimum value, if any, shall be as agreed upon and stated on the order.

3) Shall not be intentionally added.

4) Shall not be intentionally added without specific approval of purchaser. Analysis of Ce not required if not added.

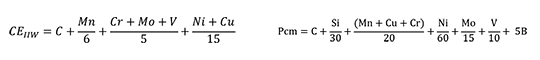

Carbon Equivalent

Tolerances

Thickness, width, and length tolerances for API 2MT1 steel plate are in accordance with the requirements of ASTM A6. The flatness tolerance for as- supplied product is ½ ASTM A6.

Delivery Conditions

API 2MT1 steel plate is supplied in the as-rolled (hot rolled or controlled rolled) or TMCP condition.

Weldability

Welding of API 2MT1 shall be performed in accordance with the applicable welding code. In the absence of a specified welding code, the following suggested minimum preheat and interpass temperatures and welding consumables are provided. Special welding consumables and welding procedures may be required to match the base metal toughness. Low hydrogen practices are strongly recommended, including the removal of surface moisture.

Supplementary Requirements

By agreement between the purchaser and plate manufacturer, the following Supplementary Requirements may be specified on the purchase order: S1 (Ultrasonic Examination), S9 (Simulation of Post-Weld Heat Treatment), S13 (Surface Quality), S14 (Thickness Tolerance) and S15 (Manufacturing Procedure Specification [MPS]).