General Product Description

AR400F is a through-hardened, abrasion-resistant plate with a nominal hardness of 400 HBW. This product is intended for applications where a good combination of abrasion resistance, formability, and weldability is desired. AR400F is supplied in the quenched and tempered or as-quenched condition.

Applications

AR400F abrasion-resistant plate is used in equipment subjected to abrasive wear. Some potential applications for AR400F include truck beds, buckets, hoppers, chutes, crushers, conveyor troughs, bulldozers, excavators, and concrete mixer drums.

Available Dimensions

(in)

(in)

(in)

Mechanical Properties

AR400F has a nominal hardness of 400 HBW.

AR400F typical transverse tensile properties (standard plate-type tensile specimen per ASTM A370) and typical Charpy V-notch impact toughness for ¾” [19 mm] thick plate:

(HBW)

(HBW)

(%)

(ksi), not guaranteed

Mechanical Testing

Brinell hardness, HBW, according to ASTM A370, on a milled or ground surface 0.020” to 0.118” (0.5 - 3.0 mm) below the plate surface.

Chemical Composition

(ladle analysis, wt. % maximum, unless otherwise indicated)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

(max %)

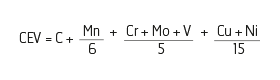

Carbon Equivalent

Tolerances

Thickness, width, and length tolerances according to ASTM A6. Flatness tolerance ½ ASTM A6.

Formability properties

The minimum recommended punch radius, R, and die-opening width, W, for plate thickness, t, for cold forming AR400F are provided in the following table. Shear burrs and heat-affected zones of thermal cut edges on or near the bend axis as well as sharp corners on edges and on gas cut or punched holes located on or adjacent to the bend axis should be removed by grinding prior cold forming.

Weldability

AR400F is weldable by conventional electric arc welding processes, using a maximum hydrogen potential of 5 ml/100g for the weld deposit and appropriate welding practice.