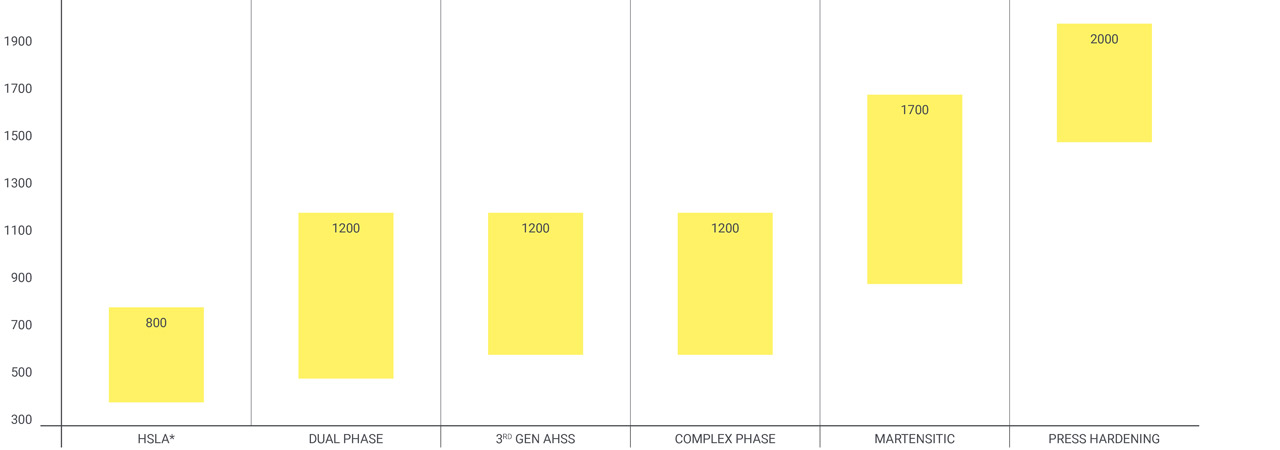

Historically, advanced high-strength steels were classified by their metallurgical type and minimum tensile strength. For example, M1200 for martensitic with a minimum TS of 1200 MPa. For the sake of simplicity during informal discussions, strength numbers can be “rounded up”.

To determine a specific grade’s actual value, look at its full steel grade name: for example, “CR290Y490T-DP” describes a DP500 steel with an actual minimum tensile strength of 490 MPa (the “490T”), as well as its minimum yield strength of 290 MPa (the “290Y”).

In any case, automakers buy advanced steels to meet either their own custom AHSS specifications, or specific national or international AHSS standards, and they clearly delineate the AHSS properties, including the minimum yield and tensile strengths.

Also note that AHSS steels’ predecessor – high-strength, low-alloy steels (or HSLA) – used designations, for example HSLA 430, that referenced the grade’s minimum yield strength and not its tensile strength.

An additional nomenclature consideration is that HSLA steels (which are sometimes further abbreviated to just “LA” in their product names) have progressed to the point where their minimum tensile strengths exceed the 440 MPa level, qualifying them for the AHSS designation.