Duroxite® overlays for extreme durability

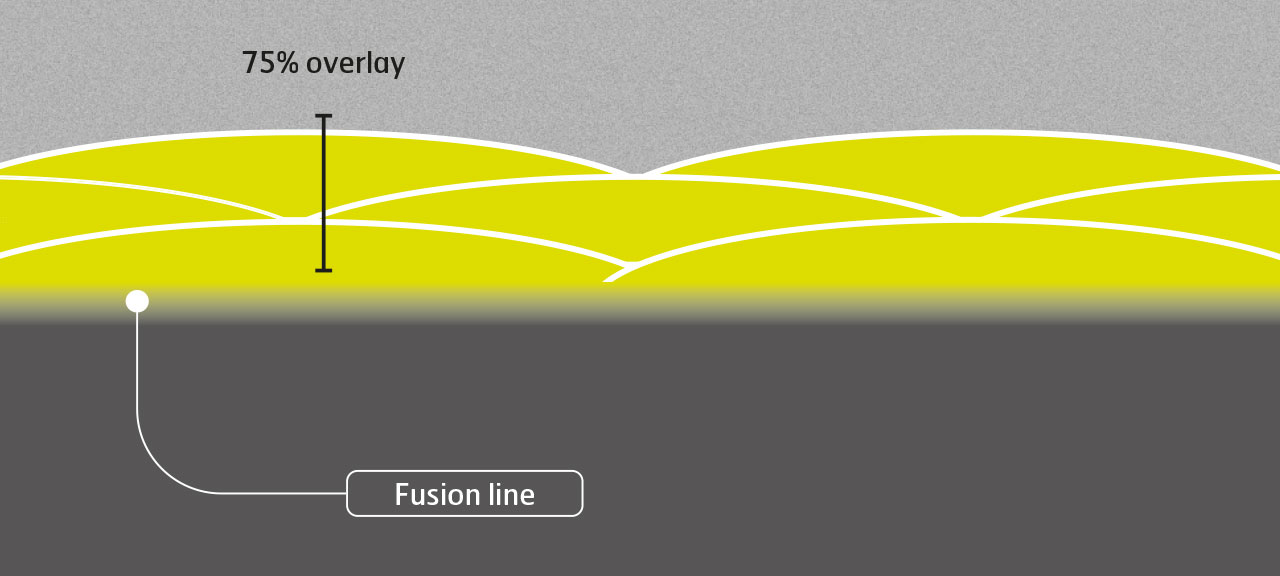

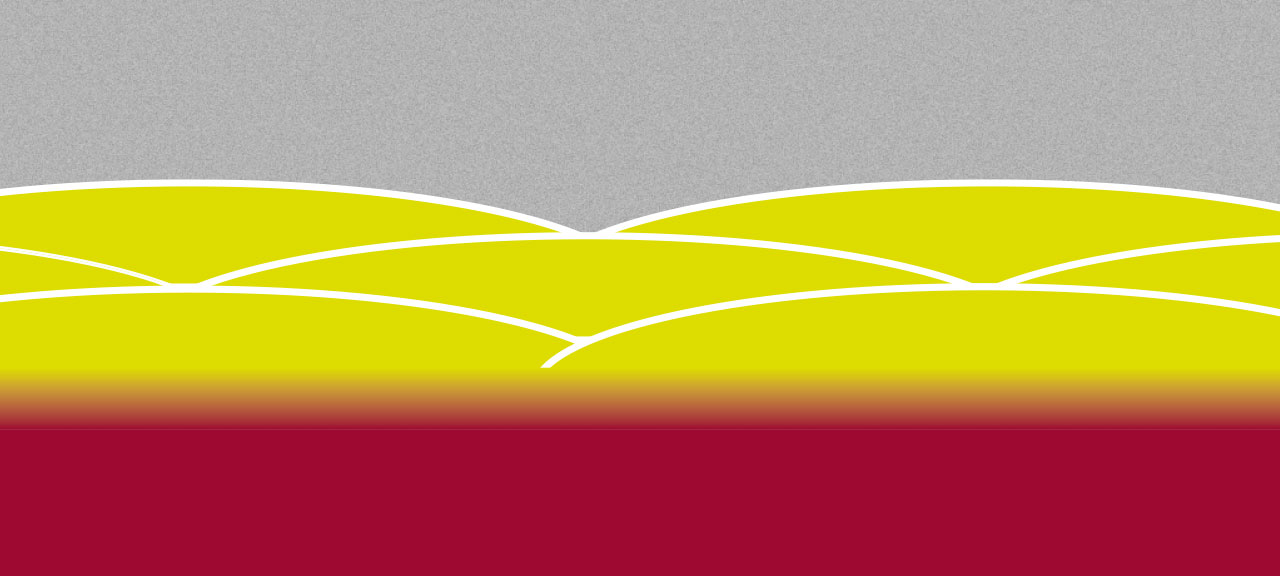

Duroxite® overlay products are designed for your most extreme wear situations with abrasion, impact, heat, metal-to-metal and erosion wear. Duroxite® fights wear for a long time thanks to its unique guaranteed wear properties down to 75% of the overlay thickness.

Product offer and datasheets Contact sales