Strenx® performance steel. Think thinner, get stronger

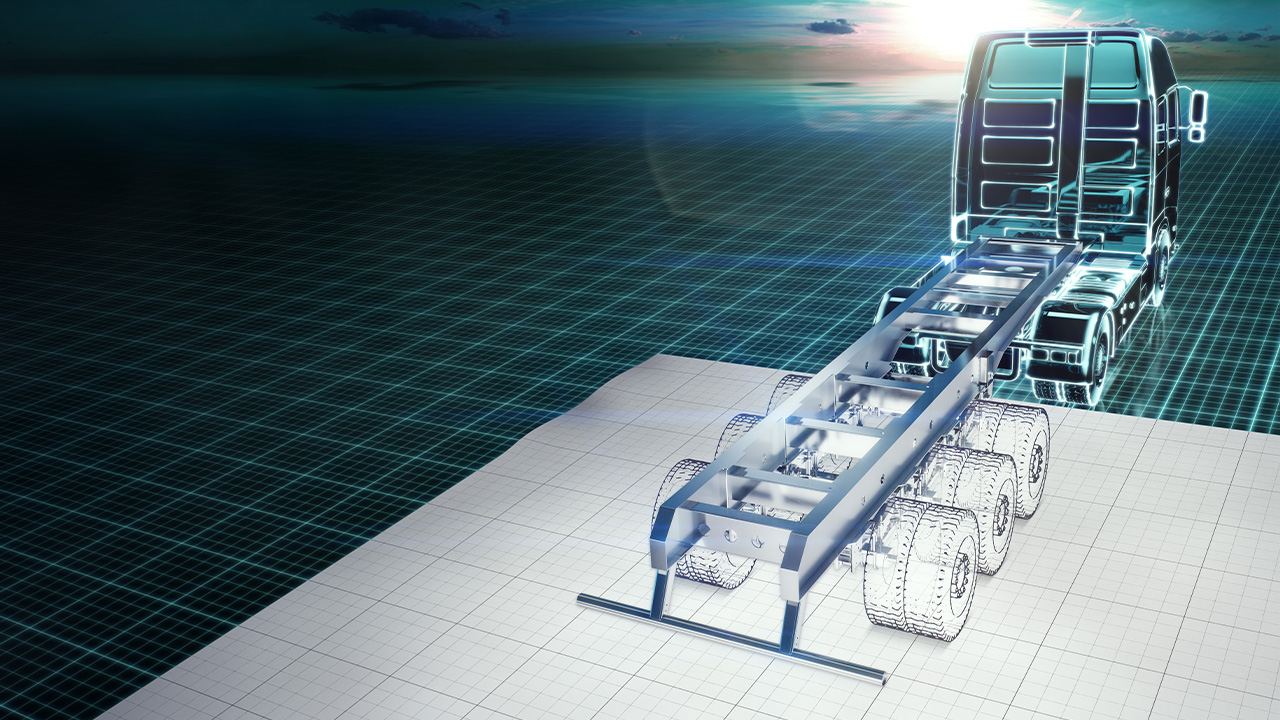

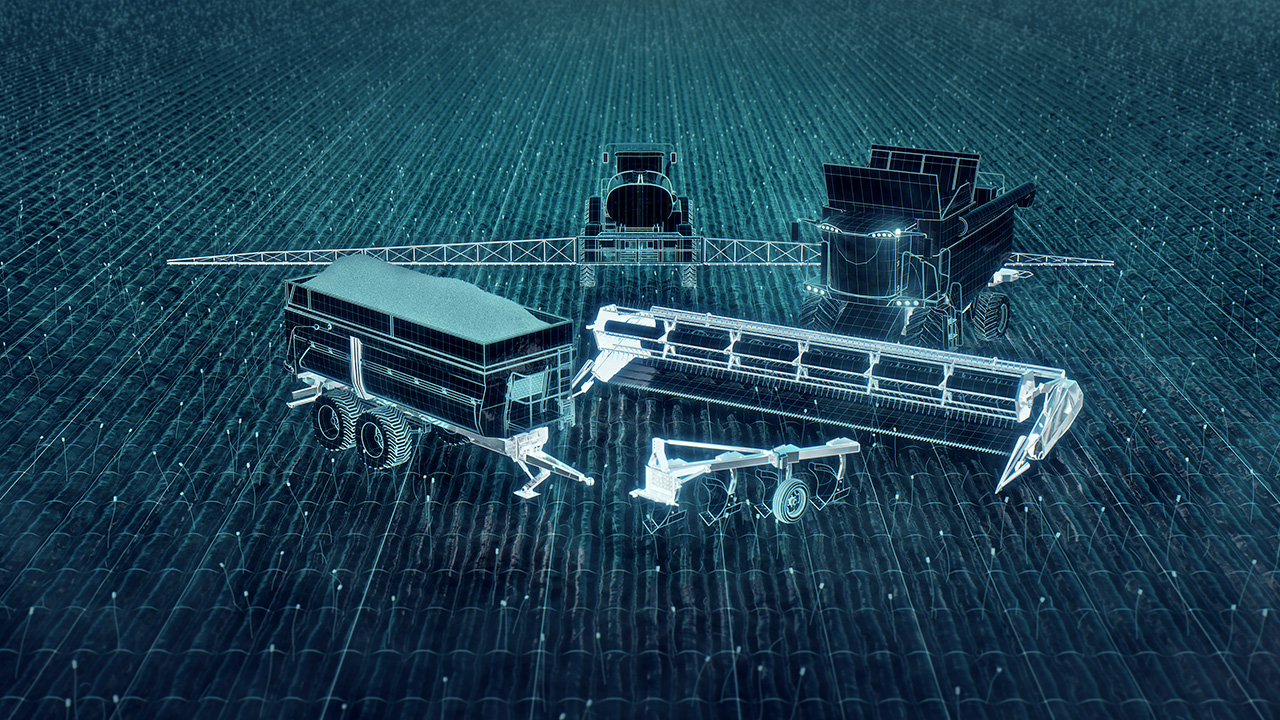

Strenx® high-strength structural steel can take your business to new heights with stronger and lighter products. Whatever your customers’ industry – transportation, lifting, agriculture or construction – Strenx® structural steel in their equipment will outperform other steels in the toughest of environments.

Product offer + data sheets To Strenx® sales form