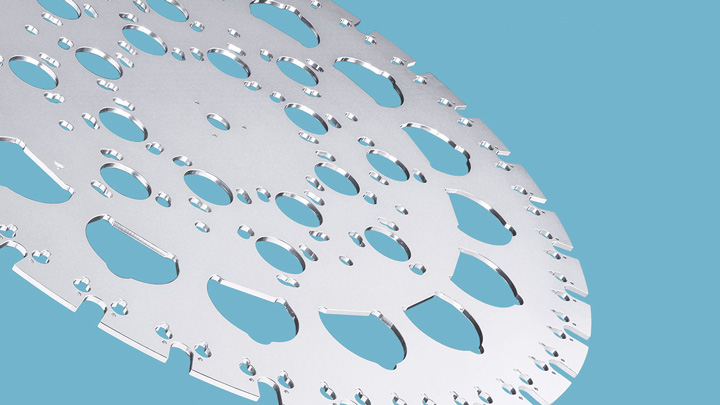

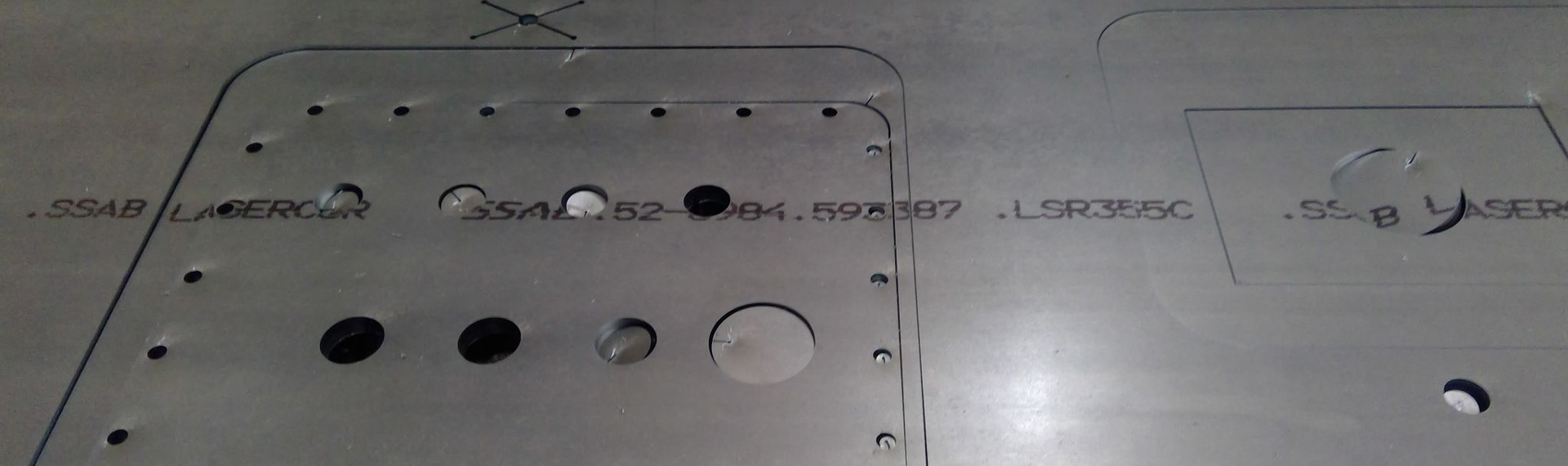

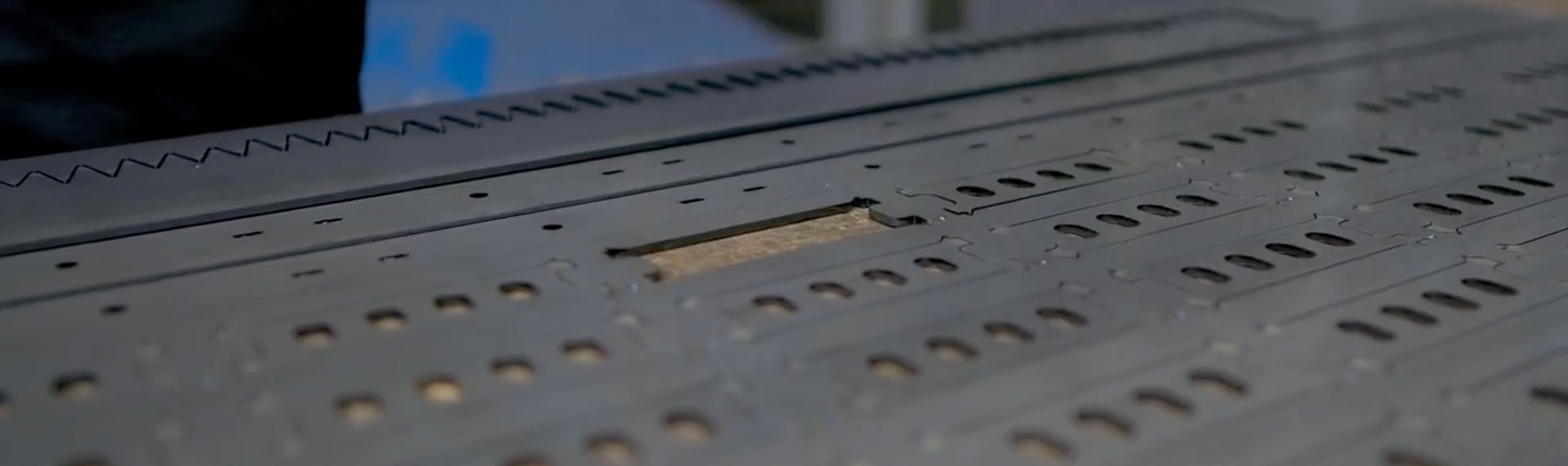

Total process control at the mill results in highly optimized, consistent chemical compositions, processed to extreme, guaranteed flatness. SSAB Laser® grades fulfill your most challenging requirements for fast and trouble-free laser cutting and cold-forming, enabling shorter production time, less need for rework, and more precise structural steel components.

- Optimized and consistent chemistry, with superior steel cleanliness

- Uniformly narrow tolerances for high dimensional accuracy

- Properties always exceed EN standards

- Enhanced impact toughness at low temperatures, down to -60°C

- Optimized surface quality for laser cutting

- Predictable and repetitive performance during cold-forming operations

- Excellent welding properties